Setting Paper in a Paper Tray

Each paper tray has been preset with paper specifications. If you want to use another paper type than any loaded in the trays, follow the procedure below to change the Paper Setting.

Load copy paper into the tray with the setting to be changed.

Press the COPY tab to display the COPY screen.

Check the Paper Setting of each tray displayed under Paper.

supplementary explanationThe screen provides Size, Name, Weight, Amount, Colored Paper, Punch, and Both Sides in a line for each tray. The Name normally shows a paper type, or a profile name if registered specifications are recalled.

Press Paper Setting.

supplementary explanationYou can make the same setting from both Paper Setting in the COPY screen and Paper Setting in the MACHINE screen.

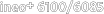

The Paper Setting screen is displayed.

Press the tray key to change the Paper Setting.

supplementary explanationTray keys are provided in the left side area of the Paper Setting screen. Pressing a tray key shows the conditions specified for that tray in the right side.

supplementary explanationIf you know the profile number of the paper condition to be recalled, press No. Recall. You can enter the profile number to easily recall the profile and configure settings.

Press Recall, Change Set, or New Settings.

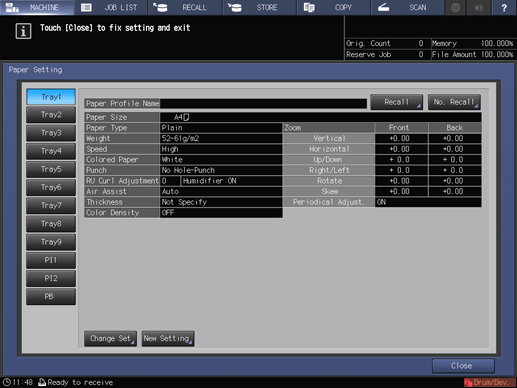

Pressing Recall displays the Recall screen, on which registered paper specifications can be selected. Proceed to step 7.

Pressing Change Set or New Settings displays the Change Individual Set screen to change the specifications individually. Proceed to step 11.

supplementary explanationPressing Change Set displays the current setting value.

supplementary explanationPressing New Settings displays the default of this machine.

Press down or up on the Recall screen to scroll to the entry of the desired specifications in the list, then press the entry.

The selected entry will be highlighted.

supplementary explanationIf registered specifications do not match with those of the selected tray, that entry will be dimmed to show unavailability. In this case, change the tray to be used.

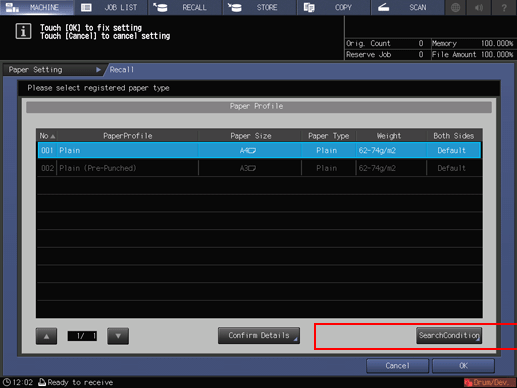

Press Confirm Details.

Details of the selected entry is displayed. When finished with checking, press Close.

Press OK on the Recall screen.

The screen returns to the Paper Setting screen.

supplementary explanationThe Paper Profile Name changes to that of recalled specifications.

Proceed to step 30, if no setting change is desired for recalled specifications.

Press Change Set.

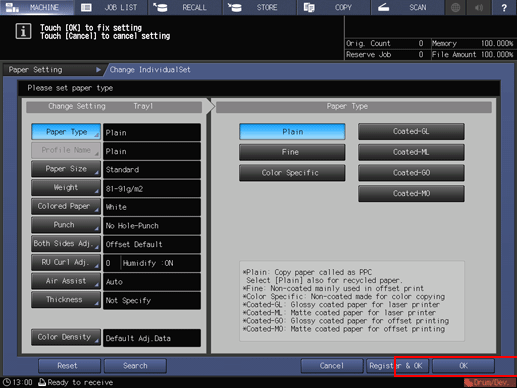

Select the desired one from the keys under Paper Type.

supplementary explanationYou can select Coated-GL, Coated-ML, Coated-GO, and Coated-MO when you set the value of Weight to 81 g/m2 / 22 lb Bond or more.

supplementary explanationPressing Search allows you to search for the registered paper profile in the currently displayed paper setting.

supplementary explanationPressing Reset allows you to reset the current setting value to the default on the machine.

Press Paper Size.

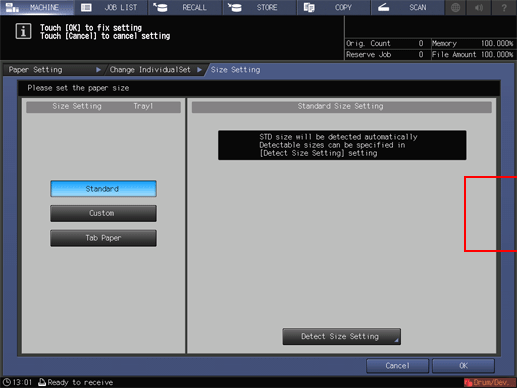

The Size Setting screen is displayed.

Select the desired one from Standard, Custom, and Tab Paper.

Proceed to step 14 for setting Standard.

Proceed to step 15 for setting Custom.

Proceed to step 16 for setting Tab Paper.

supplementary explanationIf you select the upper trayPI1 or the lower trayPI2 of Post Inserter PI-502 in step 5, Tab Paper will not be displayed.

supplementary explanationStandard and Tab Paper will not be displayed with PB selected in step 5.

With Standard selected, the machine automatically detects the standard size when loaded with standard size paper in that tray.

supplementary explanationThere is, however, a group of sizes having subtle distinctions, so that the machine cannot distinguish in the operation of size detection. Let the machine detect a specific size by identifying these sizes as any one of them.

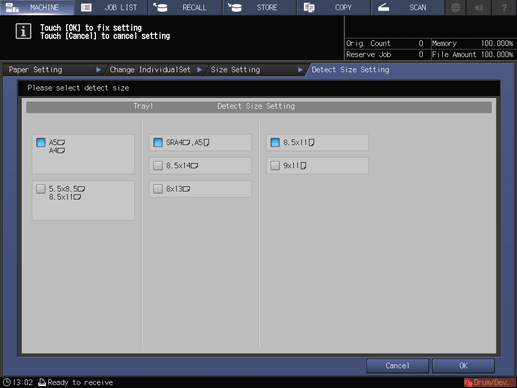

Press Detect Size Setting. The Detect Size Setting screen is displayed.

Groups of indistinguishable sizes are arranged in columns. Press the desired size in each column to select it. Press OK.

supplementary explanationDetectable sizes may vary depending on whether ON or OFF is selected for the use of K Size in the Administrator Setting provided on the Utility Menu screen. For details, refer to [K Size].

supplementary explanationDetectable standard sizes vary depending on the paper tray.

Proceed to step 17.

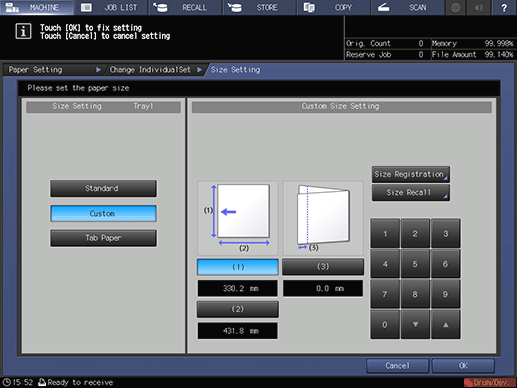

If you select Custom, the Custom Size Setting screen is displayed.

To specify a custom size:

supplementary explanationPress (1), then use the touch panel keypad, downup, or the keypad on the control panel to enter the desired widthwise dimension.

supplementary explanationPress (2), then use the touch panel keypad, downup, or the keypad on the control panel to enter the desired lengthwise dimension.

supplementary explanationPress (3), then use the touch panel keypad, downup, or the keypad on the control panel to enter the desired trimming amount for covers used in Fold & Staple/Multi Half Fold mode. The button to enter the trimming amount is displayed on the machine with Saddle Stitcher SD-506 or Saddle Stitcher SD-513 mounted.

To register a specified custom size:

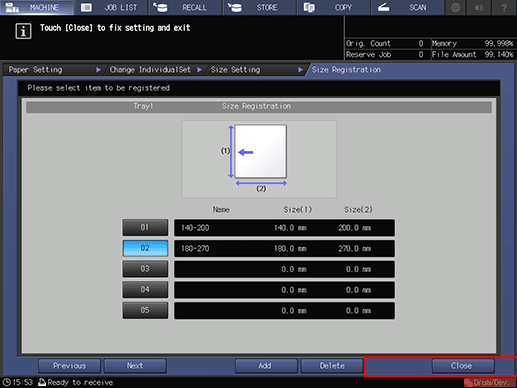

supplementary explanationAfter entering the value, press Size Registration. The Size Registration screen is displayed.

supplementary explanationDisplay the desired entry, using Previous and Next as needed to scroll. Entries from 01 to 20 are provided on the screen.

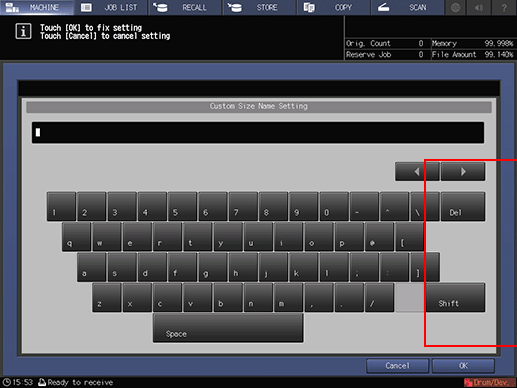

supplementary explanationPress the number key on the left side of the desired entry, then press Add. The Custom Size Name Setting screen is displayed.

supplementary explanationEnter the desired name. Up to 20 one-byte characters can be entered.

supplementary explanationPress OK.

To recall a registered custom size:

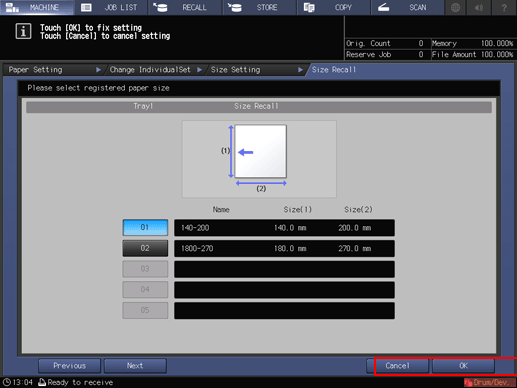

supplementary explanationPress Size Recall. The Size Recall screen is displayed.

supplementary explanationDisplay the desired custom size, using Previous and Next as needed to scroll. Entries from 01 to 20 are provided on the screen.

supplementary explanationPress the number key of the custom size to be used, then press OK.

Proceed to step 17.

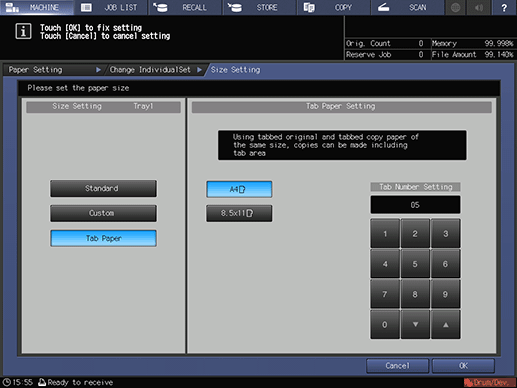

Selecting Tab Paper displays the Tab Paper Setting screen.

Select either A4Tlong edge feed or 8.511Tlong edge feed.

Use the touch panel keypad, down, up, or the keypad on the control panel to enter the number of tabs. Setting range for the number of tabs is from 1 to 15.

Press OK.

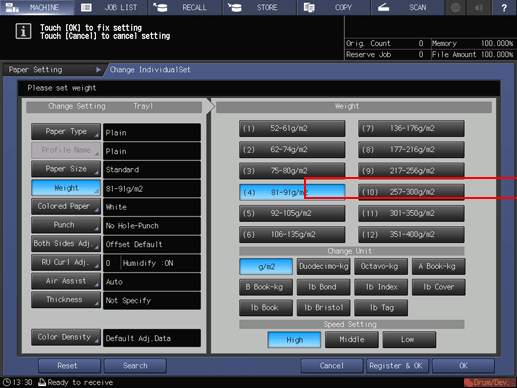

Press Weight.

The Weight screen is displayed. Select the desired weight key under Weight.

supplementary explanationThe keys (1) 52-61 g/m2 / (1) 14-15 lb Bond, (2) 62-74 g/m2 / (2) 16-19 lb Bond, (3) 75-80 g/m2 / (3) 20-21 lb Bond, (9) 217-256 g/m2 / (9) 58-68 lb Bond, (10) 257-300 g/m2 / (10) 69-81 lb Bond, (11) 301-350 g/m2 / (11) 82-93 lb Bond, and (12) 351-400 g/m2 / (12) 94-106 lb Bond are unavailable for the cover trayPB of Perfect Binder PB-503.

supplementary explanationThe keys (11) 301-350 g/m2 / (11) 82-93 lb Bond and (12) 351-400 g/m2 / (12) 94-106 lb Bond are unavailable for the upper tray [PI1] and lower tray [PI2] of Post Inserter in Folding Unit FD-503. In addition, when those trays are loaded with covers for perfect binding to be made on the machine mounted with Perfect Binder PB-503, Start on the control panel does not function with (1) 52-61 g/m2 / (1) 14-15 lb Bond, (2) 62-74 g/m2 / (2) 16-19 lb Bond, (3) 75-80 g/m2 / (3) 20-21 lb Bond, (9) 217-256 g/m2 / (9) 58-68 lb Bond, and (10) 257-300 g/m2 / (10) 69-81 lb Bond selected.

supplementary explanationThe keys (11) 301-350 g/m2 / (11) 82-93 lb Bond and (12) 351-400 g/m2 / (12) 94-106 lb Bond are unavailable for the upper tray [PI1] and lower tray [PI2] of Post Inserter PI-502.

Select the desired unit key under Change Unit. The screen displays the paper weight in the selected unit.

Process speed can be switched using the keys under Speed Setting. Change the process speed when toner fixability is not sufficient. Middle is available only in ineo+ 6100.

Press Colored Paper.

Select a desired Colored Paper key.

To specify a desired color name:

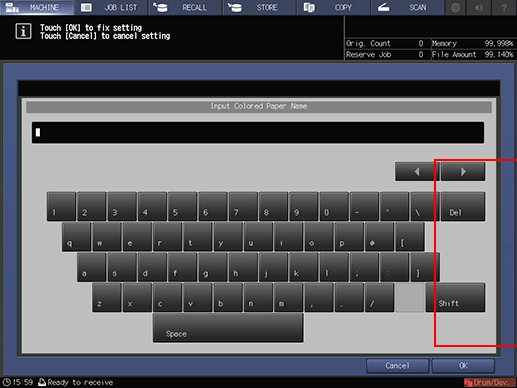

Press User Color. The Input Colored Paper Name screen is displayed.

Enter the desired color name. Up to 20 one-byte characters can be entered.

Press OK.

supplementary explanationTo change the specified color name, press Input Color Name to display the Input Colored Paper Name screen and rename it.

To register a desired color name:

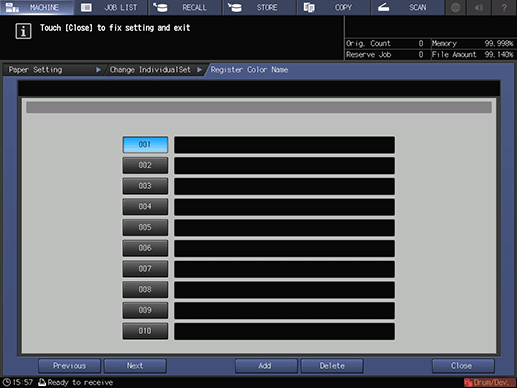

Press Register. The Register Color Name screen is displayed.

Display the number key to be registered, using Previous and Next as needed to scroll. Entries from 001 to 100 are provided on the screen.

Press the number key to be registered, then press Add.

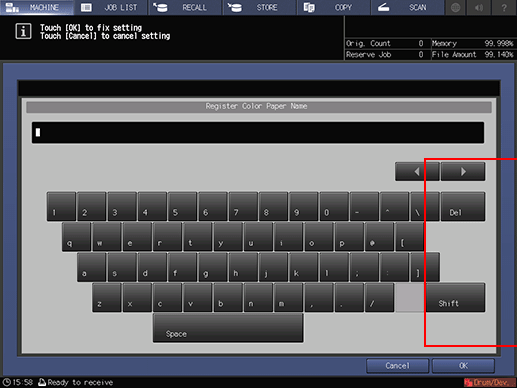

Enter the color name to be registered, then press OK.

supplementary explanationTo delete a registered color name, press the number key to be deleted, then press Delete.

To recall a registered color name:

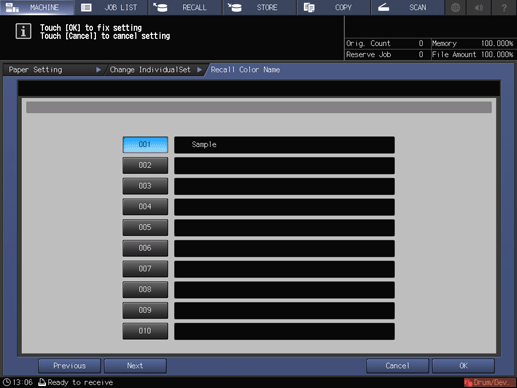

Press Recall. The Recall Color Name screen is displayed.

Display the desired number key, using Previous and Next as needed to scroll. Entries from 001 to 100 are provided on the screen.

Press the number key on the left side of the color name to be used, then press OK.

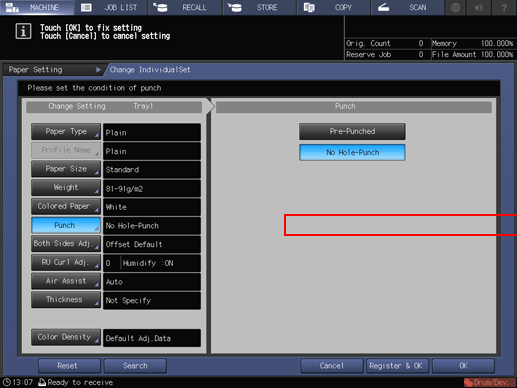

Press Punch.

Select Pre-Punched when loading sheets with punched holes, and select No Hole-Punch when loading sheets without punched holes.

Press Both Sides Adj..

The Both Sides Adjust screen is displayed.

For details about Both Sides Adj., refer to What is Both Sides Adjustment?.

Select Gap to adjust the back side based on the front side.

Select Front or Back to adjust the front and back sides separately.

When you select Gap for adjustment, enter the amount of the gap (amount of movement on the back side based on the front side) between the front and back side on the chart in each frame, and then press Adjustment Start.

If you change settings of Zoom, Image Shift, Rotate/Skew, and Chart Adjustment for Front or Back, or perform the Gap adjustment, the indication of Both Sides Adjust on the Change Individual Set screen is changed to Offset Changed.

If you press Clear, settings with related keys highlighted are restored to default values.

Take note of that pressing Reset (Front/Back) at the lower center of the screen restores default values for settings with related keys not highlighted, in addition to settings with related keys highlighted.

If Integrated Color Care Unit IQ-501 is mounted on this machine, you can select AutoMeasure to automatically make the both side adjustment.

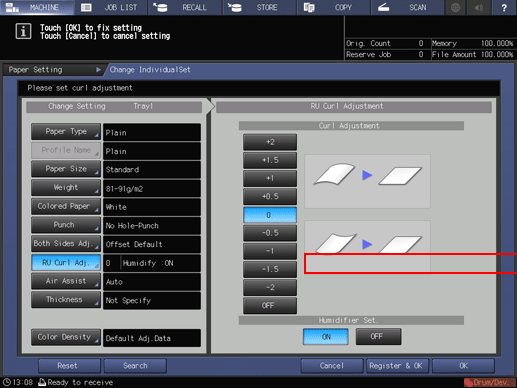

Press RU Curl Adj..

The RU Curl Adjustment screen is displayed.

For details about Curl Adjustment, refer to [Curl Adjustment].

supplementary explanationIf the paper weight of Color Specific is set to 52 g/m2 to 135 g/m2 / 14 lb Bond to 36 lb Bond, and the paper weight of Coated-GL, Coated-ML, Coated-GO, and Coated-MO is set to 81 g/m2 to 135 g/m2 / 22 lb Bond to 36 lb Bond, the Humidifier Set. and ON/OFF selection become unavailable.

supplementary explanationHumidifier Set. is displayed only when Humidifier HM-101 is mounted.

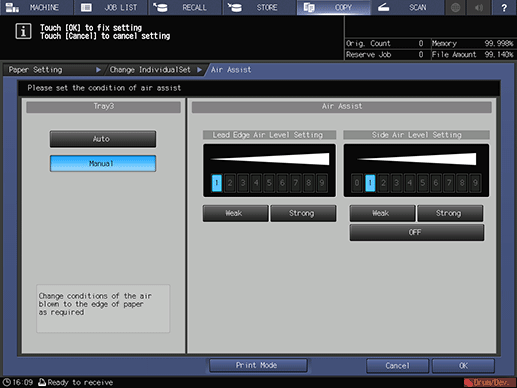

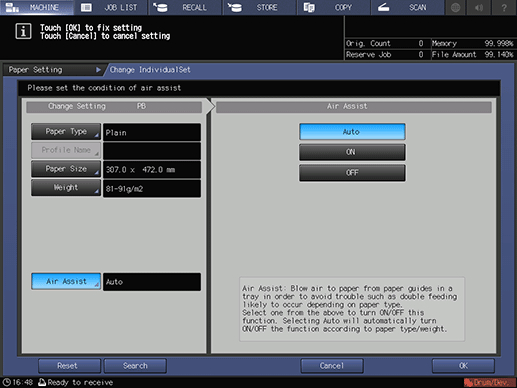

Press Air Assist.

If you select Tray1 to Tray9 of Paper Feed Unit PF-707m or Paper Feed Unit PF-711 in step 5 and then press Air Assist, the following Air Assist screen is displayed.

Select Auto or Manual.

supplementary explanationIf you select Manual, 9 air levels are available by pressing Weak / Strong in Lead Edge Air Level Setting and Side Air Level Setting.

OFF can also be selected in Side Air Level Setting.

If you select PB of Perfect Binder PB-503 in step 5 and then press Air Assist, the following Air Assist screen is displayed.

Select Auto, ON, or OFF, as desired.

Press OK.

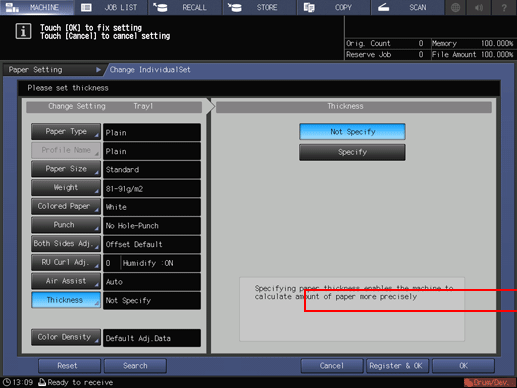

Press Thickness.

supplementary explanationThickness is displayed when Image Controller IC-604 is mounted.

Select the desired button from under Thickness.

Selecting Specify displays the touch panel keypad. Use the touch panel keypad or downup to enter the adjustment value. Available range is from 0.050 mm to 0.500 mm.

supplementary explanationThe entered value is displayed on the right side of Thickness in the left side area of the screen. Entering a value less than 0.050 mm automatically sets the value to 0.050 mm.

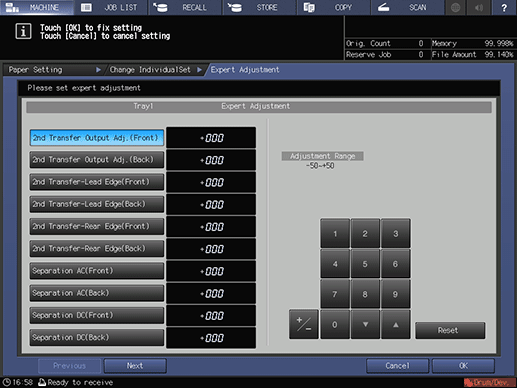

Press Expert Adj..

supplementary explanationIn the default setting, Expert Adj. is not displayed. To make the expert adjustment from the Paper Setting provided on the MACHINE screen or COPY screen, contact your service representative.

supplementary explanationFor the Pre-regist. Loop Adj.(Front) that is displayed by pressing Next twice from 2nd Transfer Output Adj. (Front), select the button for the item you want to adjust and press the touch panel keypad, down, up, or the keypad on the control panel to enter values.

supplementary explanationPress +/- to specify the value to be positive or negative.

supplementary explanationPress Next to display the setting screen.

supplementary explanationMake settings for the following items.

Toner Amount Save, Dens. Adj. Per Tray (YMC), Dens. Adj. Per Tray (K), Double Feed Detection, Mis-centering Detect JAM, Int. Transfer Separation, Thick BK Mode,Feed Correction, PFU Paper Float Timing, Lower Fusing Roller Cooling Fan Air Level, Fusing Air Separation Air Level Setting, PFU Suction Air Level Setting, Output Paper Separation Setting

supplementary explanationPress OK to complete the setting. To cancel the change, press Cancel.

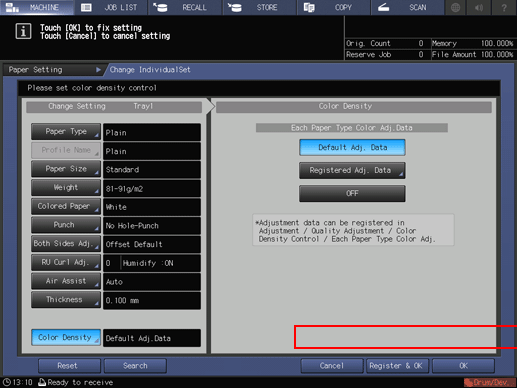

Press Color Density.

The Color Density screen is displayed.

supplementary explanationThis setting is enabled when ON is selected for Use Color Density Control, accessed from Color Density Control - Basic Setting on the Adjustment Menu screen.

supplementary explanationFor details about Color Density Control, refer to Overview of Color Density Control.

Select Default Adj. Data, Registered Adj. Data, or OFF, as desired.

supplementary explanationWith Default Adj. Data selected, the machine performs Gamma Correction (Color Density Control) with reference to the adjustment data preset on the machine.

supplementary explanationSelecting Registered Adj. Data displays the Each Paper Type Color Adjustment List screen.

Select the desired registration name, then press OK. The list displayed on the Each Paper Type Color Adjustment List screen indicates color sensor adjustment values per paper type registered in Color Density Control of the Adjustment Menu screen.

supplementary explanationSelecting OFF deactivates the Color Density Control function.

Paper Setting is then completed.

supplementary explanationTo apply and register paper conditions, press Register & OK. Proceed to step 27.

supplementary explanationTo apply paper conditions without registration, press OK. Proceed to step 30.

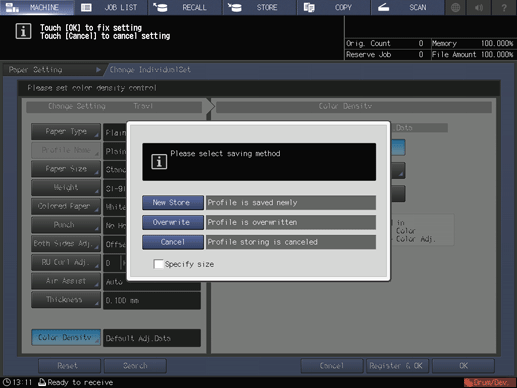

Select a storage method.

supplementary explanationWhen pressing New Store, go to step 28.

supplementary explanationIf Overwrite is selected, data is overwritten by the registered paper condition.

supplementary explanationTo also store the paper size, select the Specify size check box.

supplementary explanationIf the Specify size check box is not selected, the paper size is stored as Don't Care.

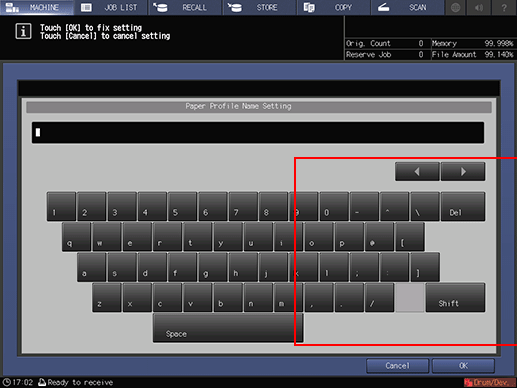

Enter the desired paper profile name.

supplementary explanationUp to 25 two-byte characters or 50 one-byte characters can be entered for the paper profile name.

Press OK.

Paper conditions are registered in the profile of the lowest number.

The screen returns to the Paper Setting screen.

Press Close.

The screen returns to the MACHINE screen or the COPY screen.