Configuring Advanced Automatic Inspection Settings in Advance

Configure settings such as inspection standards and actions to be performed when something is detected.

You can configure settings from any of the following.

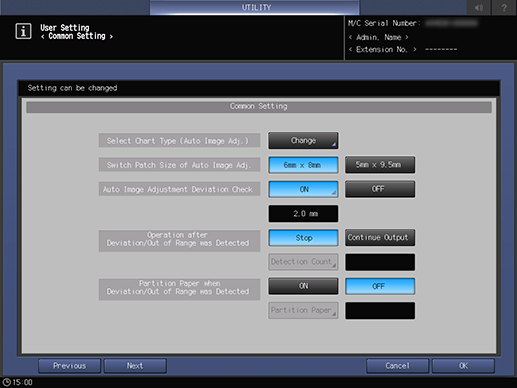

From [User Setting]:

Control panel - Utility/Counter - [User Setting] - [Common Setting]

From [Administrator Setting]:

Control panel - Utility/Counter - [Administrator Setting] - [Common Setting]

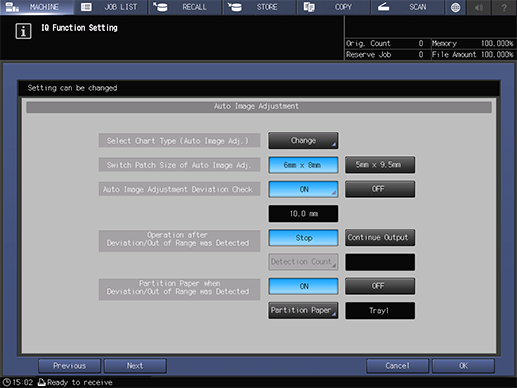

From [IQ Function Set.]:

[IQ Function Set.] on the [MACHINE] screen

- If Intelligent Quality Care Unit IQ-501 is not mounted, [IQ Function Set.] is not displayed.

- For details about setting items, refer to [Common Setting].

Setting item | Description |

|---|---|

[Operation after Deviation/Out of Range was Detected] | Set the operation to be performed when a deviation or out of range image is detected. |

[Partition Paper when Deviation/Out of Range was Detected] | Set to insert partition paper when output paper does not satisfy the standard. |

[Automatic Reprint when Deviation/Out of Range was Detected] | Set to re-print a job when output paper does not satisfy the standard. |

[Output Tray for Out of Range] | Set the tray to eject the output paper that does not satisfy the standard. |

[Create Auto Inspection Report] | Set to create an automatic inspection result report. |

[Create Report of Completed Job] | Set to create reports of inspection results that are within the standards. |

[Automatic Inspection Level Setting] | Set the inspection standard for automatic inspection. |

[Reference Image Automatic Deletion] | Set to automatically delete the reference image created by automatic inspection. |

[Reference Image Type Selection] | Select a reference image type. It is recommend that you set to [RIP Data]. Inspection Enhancement Kit UK-311 is required to use this function. |

[Setting for Inspect. of Excluded Areas] | Set the default of the Inspection Excluding Area. |

[Counted Error by Each Level] | Totalize the detected stains and omissions by level and display the result in the automatic inspection result report. |

[Text for OCR] | Set the characters that can be read with OCR. |

[Output Tray for Reference Image Job] | Set the destination where to output a reference image job. |

in the upper-right of a page, it turns into

in the upper-right of a page, it turns into  and is registered as a bookmark.

and is registered as a bookmark.