Cleaning

This section describes the parts and intervals to clean the main body.

Using tack paper may hinder proper conveyance of paper due to glue sticking to the components. In order to realize the best performance, it is recommended to clean the machine in the following frequency.

Properly clean the exterior of the machine and the control panel.

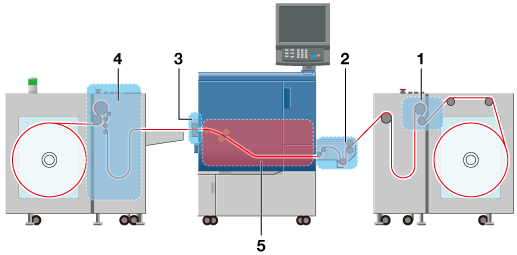

No. | Cleaning Parts | Recommended Intervals |

|---|---|---|

1 | Roll Winder RW-101 | Daily or every 1,200 m / 3936.96' of printing |

2 | Leading section | |

3 | Delivering section | |

4 | Roll Winder RW-201 | |

5 | Internal Machine Items | Weekly or every 6,000 m / 19684.8' of printing |

For details about cleaning, refer to the following:

When cleaning, be careful not to injure your hands with the edges of the metal plates and paper.

Depending on paper, cleaning may need to be performed at intervals shorter than the recommended ones. Follow the procedures below to timely check for glue and perform cleaning.

Open the top cover of Roll Winder RW-201 and make sure that glue does not stick to the ends of the rubber roller and the media guide. If any glue sticks to the parts, clean them. For details, refer to Cleaning Roll Winder RW-201.

Make sure that glue does not stick to Roll Winder RW-101, leading section, delivering section, and internal machine items. If any glue sticks to the parts, clean them.

For details, refer to each of the following pages.