Adjusting the Positions of the Media and Parts

Adjust the positions of the media and parts before operating the machine.

When cleaning is complete, be sure to adjust the positions of the media and parts. Otherwise, the media may meander or move sideways while being fed.

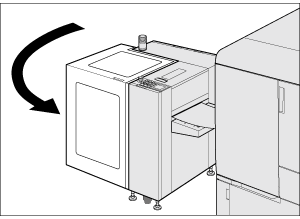

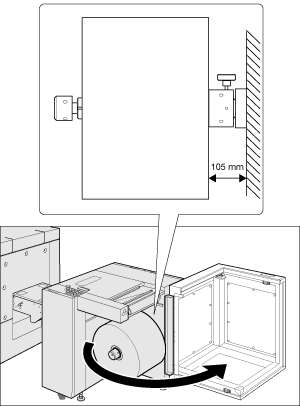

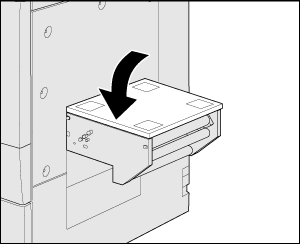

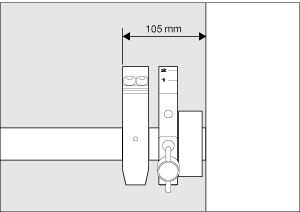

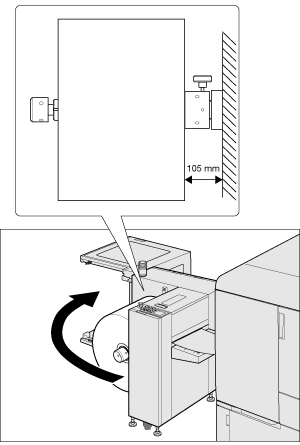

Open the media cover of Roll Winder RW-101 and make sure that the media is positioned 105 mm (±0.25 mm) / 4.13" (±0.01") away from the metal plate of the inside of Roll Winder RW-101.

Close the media cover of Roll Winder RW-101.

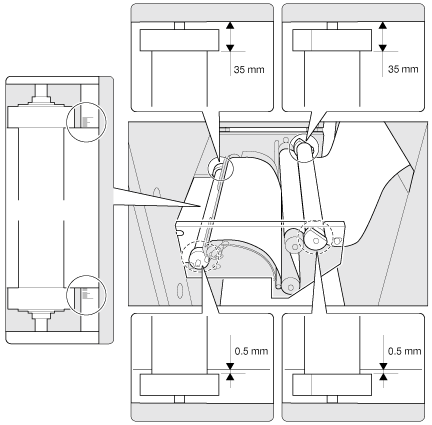

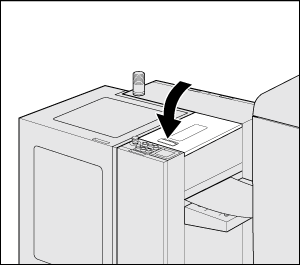

Open the top cover of the leading section and check the following.

The media guide (back side) of the tension roller 1 is positioned 35 mm (±0.25 mm) / 1.38" (±0.01") away from the metal plate.

The media guide (front side) of the tension roller 1 is positioned 0.5 mm (±0.25 mm) / 0.02" (±0.01") away from the media.

The restriction guide (back side) of the restriction roller is positioned 35 mm (±0.25 mm) / 1.38" (±0.01") away from the metal plate.

The restriction guide (front side) of the restriction roller is positioned 0.5 mm (±0.25 mm) / 0.02" (±0.01") away from the media.

The media does not protrude from each guide.

The media is centered against the scale marks indicated on the main body.

Close the top cover of the leading section.

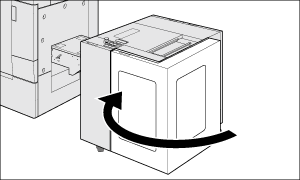

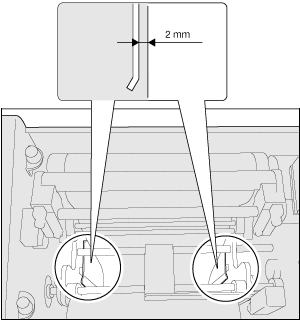

Open the top cover of Roll Winder RW-201 and make sure that the side plates are positioned 2 mm (±1 mm) / 0.08" (±0.04") away from the edges of the media.

Make sure that the media guide (back side) is positioned 105 mm (±0.25 mm) / 4.13" (±0.01") away from the metal plate.

Position the media guide (front side) at 0.5 mm (±0.25 mm) / 0.02" (±0.01") away from the media.

Close the top cover of Roll Winder RW-201.

Open the media cover of Roll Winder RW-201 and make sure that the media is positioned 105 mm (±0.25 mm) / 4.13" (±0.01") away from the metal plate.

Close the media cover of Roll Winder RW-201.