Prepare the Machine

Prepare the machine to print.

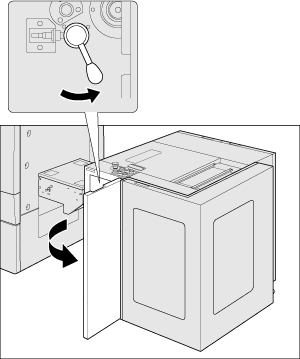

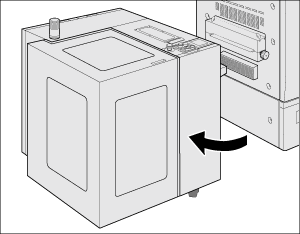

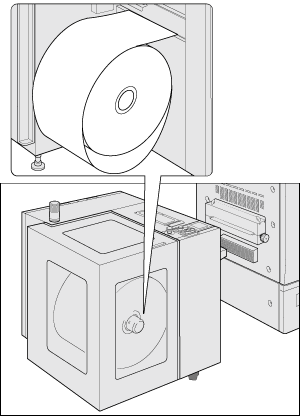

Open the front door of Roll Winder RW-101 and move the lever to attach the rubber roller.

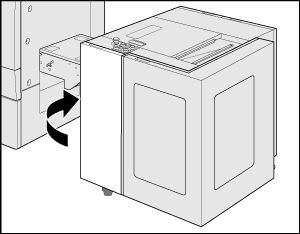

Close the front door of Roll Winder RW-101.

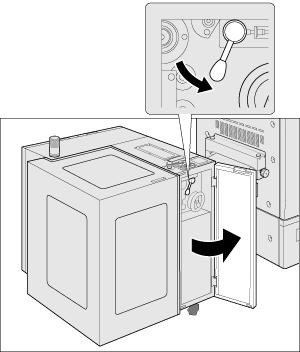

Open the front door of Roll Winder RW-201 and move the lever to attach the rubber roller.

Close the front door of Roll Winder RW-201.

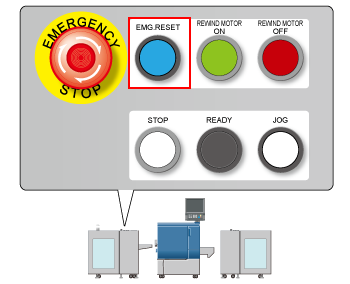

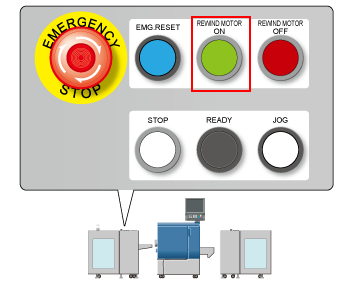

If the machine is in the emergency stop status, press EMG.RESET on the control panel of Roll Winder RW-201 to cancel emergency stop.

Confirm all the covers are closed, press EMG.RESET to reset the emergency stop.

If EMERGENCY STOP is pressed, unlock the button, and then press EMG.RESET.

For details on how to unlock EMERGENCY STOP, refer to Control panel (Roll Winder RW-101/Roll Winder RW-201).

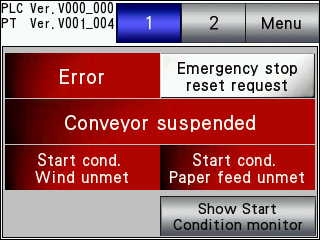

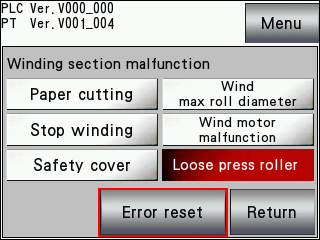

When an error has occurred, clear the error.

Check the location of the error on the error screen, clear the error, and then press [Error reset].

For details, refer to Error Screen.

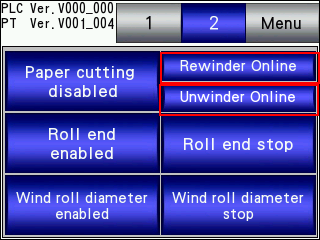

On the touch panel of Roll Winder RW-201, select [Main menu] - [1,Machine state/2,Machine setting] - [2] to set [Unwinder Online], [Rewinder Online].

Press REWIND MOTOR ON on the control panel of Roll Winder RW-201.

When turning ON the winding motor, make sure that there is no slack on the media. Slacks may result in paper being torn.

When the machine is ready to print, the LEDs displayed under Roll Winder RW-101, Roll Winder RW-201 on the [MACHINE] screen on the touch panel of the main body light in blue. The message [Ready to print] also appears.

[Start cond. Wind met] and [Start cond. Paper feed met] are displayed in green on the touch panel of Roll Winder RW-201.