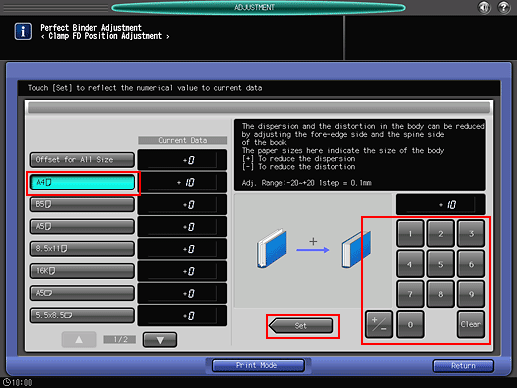

Perfect Binding: Adjusting the Clamp FD Position

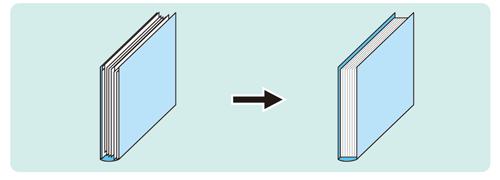

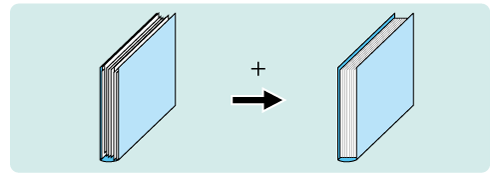

Change the adjustment width in paper feed direction if output sheets show misalignment in a body set.

The sizes referred to in this section are those of body sets corresponding to cover paper sizes.

As an example, this section explains how to adjust a misalignment of 1 mm.

• Meaning and Purpose of Clamp FD Position Adjustment

When there is misalignment in the body sets, this function allows you to adjust the cut edge side and spine side by specifying the desired values.

Negative values reduce the curve.

Positive values reduce misalignment.

• When to perform

When the body sets for perfect binding are misaligned in paper-feed direction

• Intended Environment

Image Controller | Image Controller IC-602 |

Mounted finisher | Perfect Binder PB-503 |

* The sample screen may be different from the actual display depending on your system environment.

Check for misalignment in the body sets of a perfect-bound book.

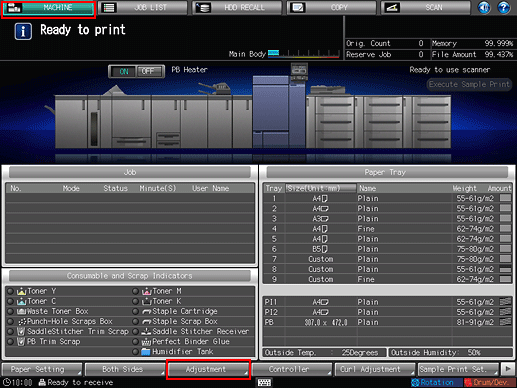

On the touch panel of the main body, press [Adjustment] on the [MACHINE] screen.

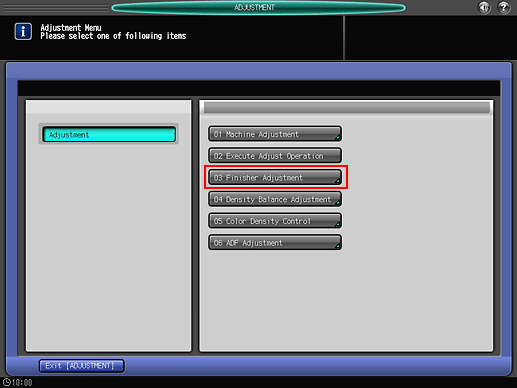

Press [Finisher Adjustment] on the [Adjustment Menu] screen.

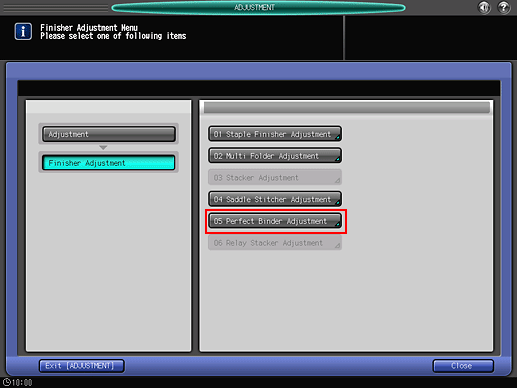

Press [Perfect Binder Adjustment] on the [Finisher Adjustment] menu.

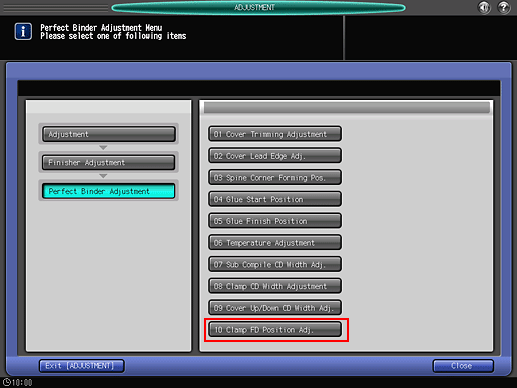

Press [Clamp FD Position Adj.] on the [Perfect Binder Adjustment] menu.

Select the paper size to adjust. Enter the adjustment value and press [Set].

Example: Reduce a 1 mm misalignment for [A4].

Item

Setting

[A4]

Reducing the 1 mm misalignment (10)

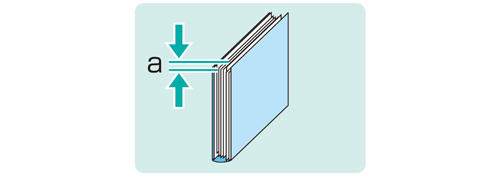

Press [1], [0], and [Set] to enter the value [10]. This reduces the misalignment by 1 mm.

Press the keypad on the screen to set the value.

Use [+/-] to specify the value to be positive or negative. Set a positive value to reduce misalignment. Set a negative value to reduce curve.

The values are in 0.1 mm increments. (1 = 0.1 mm)

With a specific paper size selected, the set value becomes the sum of the entered value and the value specified for [Offset for All Size].

Pressing [Print Mode] switches the mode to print mode, which allows you to print the original.

Print the original again in perfect binding and check the alignment in the body sets.

Repeat the above steps until there is no misalignment in the body sets.