Manual Adjustment

Performing Manual Adjustment

Manually perform the gamma correction using the density sensor of Relay Unit RU-518 (hereinafter, referred to as manual adjustment). Manual adjustment is performed when you want to update Color Density Control by optional readjustment.

In Basic Setting, if you set Use Color Density Control to ON while Periodical Adj. Execution to OFF, also perform manual adjustment as necessary before running a job. The Switch Color(1st or 2nd) setting in Basic Setting is also effective for manual adjustment. Select Normal to adjust primary colors only. Select Precise to adjust both primary colors and secondary colors.

When performing manual adjustment, select the sensor adjustment data that becomes the base of correction from the following two types.

- Sensor adjustment data that has been set as default with shipment (Default Sensor Adjustment Data)

- Sensor adjustment data that is adjusted to a particular paper type and screen (Color Sensor Adjustment Data for Each Paper Type (Registered Adj. Data))

The manual adjustment must be performed for each combination of paper type and screen type.

The screen type can be changed in UTILITY. For details, refer to Custom Screen.

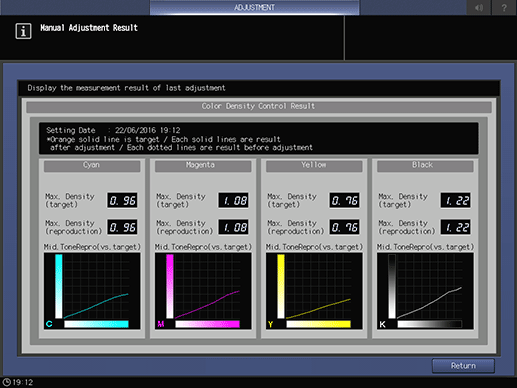

You can check the adjustment result on the screen.

Tips

The number of sheets output as charts is included in the print count.

You can add Weight to the display items on the Registered Color Density Manual Control screen. For details, contact your service representative.

Press Adjustment on the MACHINE screen to display the Adjustment Menu screen.

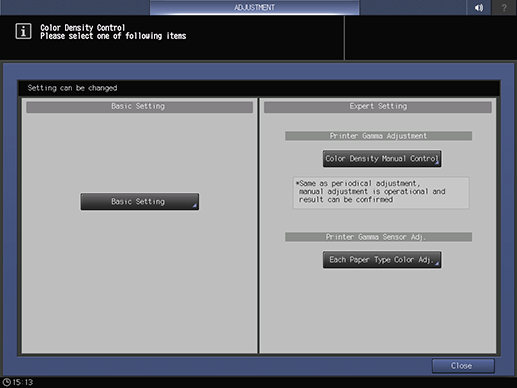

Press Quality Adjustment and Color Density Control in sequence.

The Color Density Control screen is displayed.

Press Color Density Manual Control.

supplementary explanationYou can also display the Color Density Manual Control screen by pressing Color Dens. Manual on the MACHINE screen.

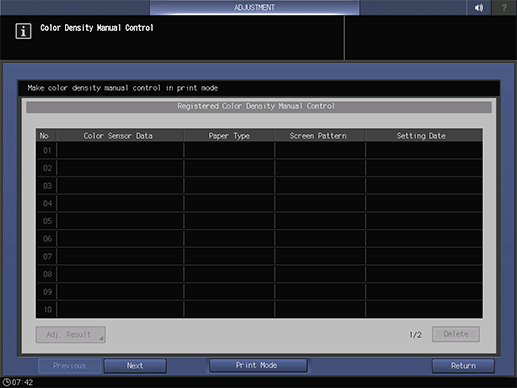

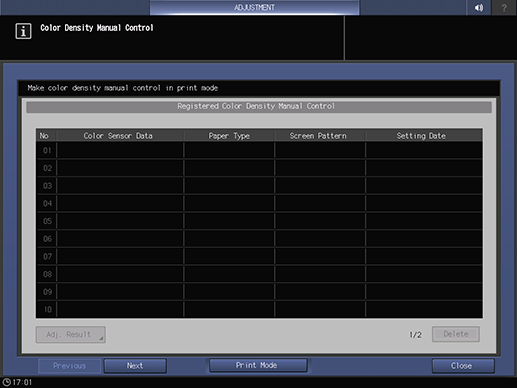

Press Print Mode.

NOTICE

The list displayed on the Color Density Manual Control screen is the history of the Color Density Manual Control. To clear the history, select the desired row (data) from the list, then press Delete. Do not select the row (data) on the list except when deleting it or displaying Adj. Result. Otherwise, the PRINT MODE screen cannot be displayed.

Up to 15 records of the history can be registered. If all 15 registrations are already made, the oldest row (data) is overwritten.

When there is no row (data) that matches all of Color Sensor Data, Paper Type, and Screen Pattern, both of Color Density Control (Target Gamma Creation) and Calibration are performed, and the result is registered as new data. When there is a row (data) that matches all the above conditions, only Calibration is performed, and the row (data) is overwritten (Setting Date is updated).

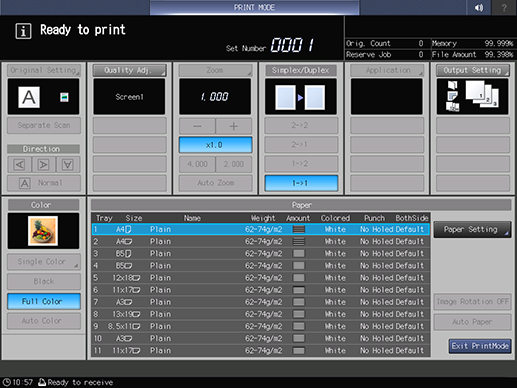

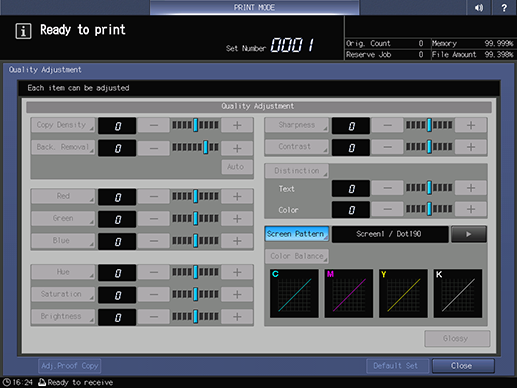

Press Quality Adj..

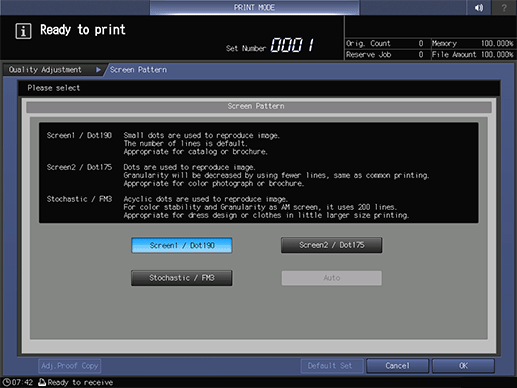

Press right on the right side of Screen Pattern to display the desired screen.

supplementary explanationAlso, you can select any desired screen after pressing Screen Pattern to display the Screen Pattern screen. Select a screen, and press OK.

supplementary explanationPress Close on the Quality Adjustment screen.

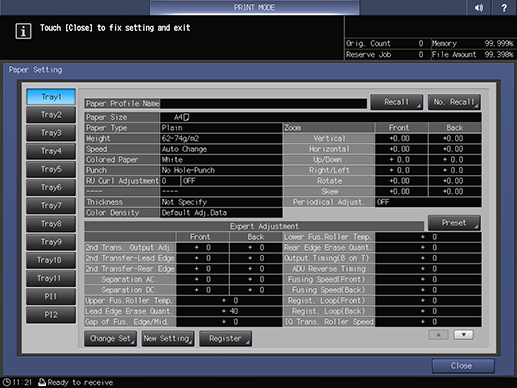

Select a tray to output the charts.

supplementary explanationPress Output Setting to display the Output Setting screen.

supplementary explanationSelect the desired output tray by pressing its key, and press OK.

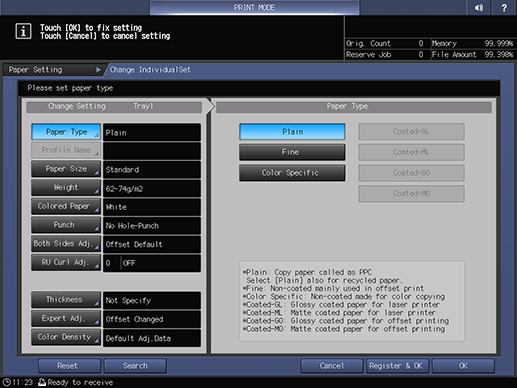

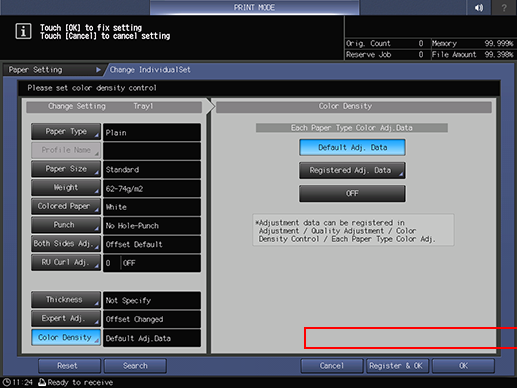

Display the Change IndividualSet screen.

supplementary explanationPress Paper Setting on the PRINT MODE screen to display the Paper Setting screen, and then press Change Set.

Select an output paper type.

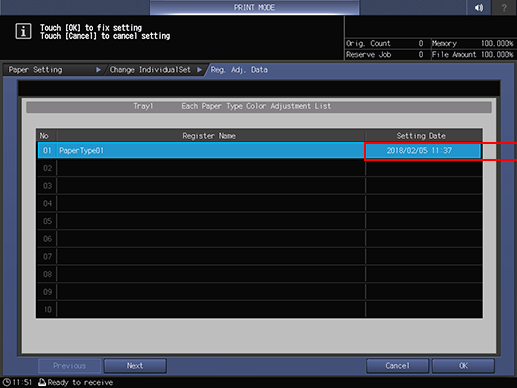

Select sensor data for each paper type to be used for the adjustment.

supplementary explanationPress Color Density.

supplementary explanationSelect Default Adj. Data to use the default sensor adjustment data provided as factory default for correction.

supplementary explanationTo use the color sensor adjustment data for each paper type for correction, press Registered Adj. Data to display the Each Paper Type Color Adjustment List screen and select the color sensor adjustment data for the desired paper type, and then press OK.

supplementary explanationWhen not applying Color Density Control to the selected tray, select OFF.

The screen returns to the PRINT MODE screen.

supplementary explanationPress OK on the Change IndividualSet screen to return to the Paper Setting screen.

supplementary explanationPress Close on the Paper Setting screen to return to the PRINT MODE screen.

Press Start on the control panel.

The charts required for the adjustment is output to the tray selected in step 7.

Press Exit PrintMode.

The screen returns to the Color Density Manual Control screen.

To check the adjustment result of manual adjustment on the screen, select a list (data) to be checked on the Registered Color Density Manual Control screen, and then press Adj. Result.

supplementary explanationPress Return to return to the Color Density Manual Control screen.

Press Return.

The screen returns to the Color Density Control screen.

Press Close.

The screen returns to the Quality Adjustment Menu screen.

Manually Performing Color Density Manual Control

Pressing Color Dens. Manual on the MACHINE screen displays the Color Density Manual Control screen.

To perform this adjustment, Relay Unit RU-518 or Integrated Color Care Unit IQ-501 is required.

Reference

For details, refer to Manual Adjustment.

Tips

You can add Weight to the display items on the Registered Color Density Manual Control screen. For details, contact your service representative.