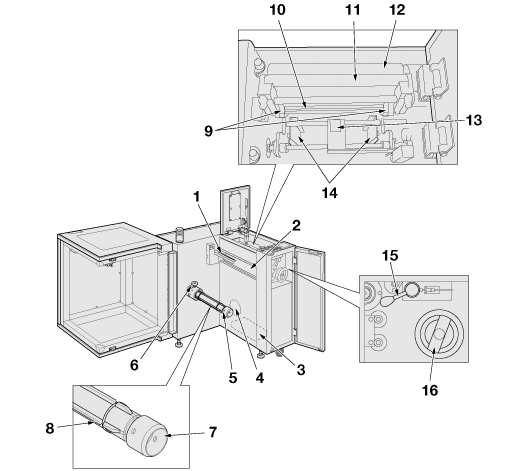

Internal Machine Items

No. | Name | Description |

|---|---|---|

1 | Media-break sensor | Detects the media break. If the sensor detects the media break, the alarm beeps and the machine stops. |

2 | Guide roller | Conveys the media. |

3 | Winding loop fan | Stabilizes the form of the loop. |

4 | Winding diameter detection sensor | Measures the diameter of the media, and alarm beeps when the media reaches maximum diameter. You can specify the machine behavior when the alarm beeps. |

5 | Winding shaft | Sets a media core and wind printed media controlling the configured media tension. |

6 | Fixing handle | Used to fix the media guide to the winding shaft. |

7 | Lug protruding/retracting handle | Turn to move up and down the lug to fix or remove the media core. |

8 | Lug | Fixes the media core to the winding shaft. |

9 | Media guide | Avoids the media from meandering. |

10 | Squeezing bar | Adjusts the media tension when winding. |

11 | Rubber roller | Holds and conveys the media. |

12 | Pull roller | Conveys the media. |

13 | Loop detection sensor | Detects an error of the amount of the media loop. |

14 | Side plate | Avoids the media from meandering when winding. The side plates moving handle allows you to adjust the width between the plates. |

15 | Lever | Attaches or detaches the rubber roller to or from the media. |

16 | Side plates moving handle | Adjusts the width of the side plates. |