Administrator Setting: Common Setting

The following features can be provided by switching the selection. This setting can also be performed by selecting Common Setting from the User Setting.

Menu item | Description | Setting value (: Default) | |

|---|---|---|---|

One Shot Message Indication Time | Select the time span to display a shot message, such as Original size is A4, in the message area of the touch panel. | 3 seconds, 5 seconds | |

Offset by Job Unit | Specify whether or not to offset the output sheets by job. | ON, OFF Also specify the number of jobs to be offset when selecting ON for this function (default: 0001). | |

Continuation Print | Specify whether or not to output multiple reserve jobs in succession without stopping the machine at a job break. | Copy ON, Copy OFF, Printer ON, Printer OFF | |

Back Side Magnification Adjustment | Specify whether to enable the lens adjustment mode. | ON, OFF | |

Fusing Stability (Mixed Media) | Select what to prioritize when fusing. | Best Quality, Better Quality, Speed | |

Prior Paper Type | Specify the temperature setting of the fusing section on standby. It can shorten the waiting time before printing by selecting a frequently used paper. | Others, Plain | |

Dash Length(Page Stamp) | Select the length of the dash to be used in a style of Page No. in Stamp. For print jobs, the setting may not be available depending on the controller type. | Long, Short | |

Center Crop Mark Trim Margin | Specify the space between the center crop mark and image area (center crop mark trim margin). | 0.0 mm to 20.0 mm (Default: 1.0) | |

Schedule Cross Axis Unit (Default) | Select the unit of horizontal axis on the Schedule screen. This setting is displayed to function on the machine mounted with Image Controller IC-605. | Timetable, Time Frame(m), Sheet Volume | |

Hold Job Status after Output (Default) | Select the default value to delete or save the data of hold job after outputting. | Delete, Save | |

Offset Output Mode | Specify how to offset the output sets. | Change Out Pos., Stop Print, Change Out Pos. + Partition Paper (Tray1, Tray2, Tray3, Tray4, Tray5, Tray6, Tray7, Tray8, Tray9, Tray10, Tray11, Bypass, PI1, PI2), Partition Paper (Tray1, Tray2, Tray3, Tray4, Tray5, Tray6, Tray7, Tray8, Tray9, Tray10, Tray11, Bypass, PI1, PI2) | |

Hold Job Direct Output (Default) | Select the default for the Direct Output check box under the Hold Job screen. ON selects the check box, and OFF clears the check box. After the change, turn OFF/ON the sub power switch to apply the setting. | ON, OFF | |

Needless Tab Paper Exit | Specify whether or not to automatically discharge the oddments of tabbed sheets loaded in a tray as a set for copy job. | ON, OFF | |

Remaining Memory (Measurement Unit) | Select the unit of displaying the remaining memory. | %, GB | |

Remaining Memory (Warning) | Select the percentage at which to give warning when the remaining memory is low. | 5% or Less, 10% or Less | |

[Proof Copy] 1 Set/1st Sheet Selection | If it is turned ON, the confirmation window is opened and you are asked to output one confirmation copy or to output only its first page when the Proof Copy is pressed. | ON, OFF | |

Both Sides Rotate/Skew | If Disable is selected, the Rotate/Skew adjustment does not become available and does not function. | Enable, Disable | |

Stop when Water Tank Near Empty | Select whether to temporarily stop a job when the humidifier tank runs low on water. | Temporary Stop, NotTemporaryStop | |

Select Chart Type (Auto Image Adj.) | Select an automatic image adjustment chart for each paper weight. The unit of weight can be switched. This option is displayed when Integrated Color Care Unit IQ-501 is mounted on the machine. | 62-74g/m2/16-19 lb Bond: Type1, Type2 75-80g/m2/20-21 lb Bond: Type1, Type2 81-91g/m2/22-24 lb Bond: Type1, Type2 92-105g/m2/25-28 lb Bond: Type1, Type2 106-135g/m2/29-36 lb Bond: Type1, Type2 136-176g/m2/37-47 lb Bond: Type1, Type2 177-216g/m2/48-57 lb Bond: Type1, Type2 217-256g/m2/58-68 lb Bond: Type1, Type2 257-300g/m2/69-81 lb Bond: Type1, Type2 301-350g/m2/82-93 lb Bond: Type1, Type2 Change Unit | |

Switch Patch Size of Auto Image Adj. | Select the patch size to be printed on a chart to perform automatic quality adjustment. This option is displayed when Integrated Color Care Unit IQ-501 is mounted on the machine. | 6mm 8mm, 5mm 9.5mm | |

Auto Image Adjustment Deviation Check | Select whether to automatically check a deviation. If you select ON, enter the specified value of a deviation. This option is displayed when Integrated Color Care Unit IQ-501 is mounted on the machine. | ON (ON: 0.5 mm to 10.0 mm, Default: 2.0), OFF | |

Operation after Deviation/Out of Range was Detected | Specify the operation to be performed when inappropriate output paper is detected. You can specify whether to stop this machine immediately or only when the number of detected errors exceeds the standard. * When the standard value for the number of detected errors is set to 0, this machine will not stop even if the number of detection increases. This option is displayed when Integrated Color Care Unit IQ-501 is mounted on the machine. | Stop, Continue Output, Detection Count (0 ~ 10 times) | |

Partition Paper when Deviation/Out of Range was Detected | Configure a setting to insert partition paper when inappropriate output paper is detected. When inserting, select the paper tray to load partition paper into. This option is displayed when Integrated Color Care Unit IQ-501 is mounted on the machine. | ON, OFF, Partition Paper ('Tray1, Tray2, Tray3, Tray4, Tray5, Tray6, Tray7, Tray8, Tray9, Tray10, Tray11, Bypass) | |

Automatic Reprint when Deviation/Out of Range was Detected | Configure a setting to perform reprinting when inappropriate output paper is detected. When reprinting is performed, paper in the machine is output once, so a page order error involving output paper does not occur. This option is displayed when Integrated Color Care Unit IQ-501 is mounted on the machine. | ON, OFF | |

Output Tray for Out of Range | Specify the tray to output paper that does not satisfy the standard. You can combine the Purge Tray of the Relay Unit RU-702 with a sub tray of the optional output unit mounted later, and also select the same tray for a job. * Paper cannot be output to the sub tray of Folding Unit FD-503, Large Capacity Stacker LS-506, or Saddle Stitcher SD-506. Also, paper cannot be output to the sub tray of Saddle Stitcher SD-513 when the Multi Tri-Fold, Fold & Staple, or Half-Fold mode is being used. * When a paper output enabled option is not connected to Relay Unit RU-702 or later, the button of RU702 + Sub tray is grayed out. This option is displayed when Integrated Color Care Unit IQ-501 is mounted on the machine. | Same as the Job, Purge Tray (RU702 Only, RU702 + Sub Tray) | |

Create Auto Inspection Report | Configure a setting to create an automatic inspection result report. When inappropriate output paper is not discharged automatically, the user deals with the inappropriate output paper based on the report. This option is displayed when Auto Inspection Unit UK-301 is mounted. | Yes, No | |

Automatic Inspection Level Setting* | Adjust the detection standard for automatic inspection. There are three levels: Essential, Standard, and Premium, for each of which you can adjust the detection standard. This option is displayed when Auto Inspection Unit UK-301 is mounted. | Detail Settings | |

| Spot Detection Level | Specify the reference value of the spot size. A spot that is over the reference size value is detected as an image failure. | Range: 1(Large) - 7(Small) |

Paper Noise Removal Level | Specify the reference value of spot density. A spot that is over the reference density value is detected as an image failure. | Range: 1(Strong) - 7(Weak) | |

Image Edge Detection Sensitivity | Specify the sensitivity of the inspection area around the edge of the image. A slight image misalignment may occur around the edge of the image even if no image failure is detected; therefore, if the sensitivity is set to a higher level, it may lead to frequent reprinting. | Range: 1(Low) - 7(High) | |

Permission Level for Spot | Specify the reference value that permits an image spot detected in a reference image. An image failure may be slipped into a reference image when it is created. If automatic inspection is performed in this status, the inspection image is detected as an error even if there is "no error". In such a case, reduce this reference value; an image failure of a reference image is permitted to a certain degree, which enables smooth printing. | Range: 1(Large) - 7(Small) | |

Wait Screen for Automatic Inspection | Set the automatic inspection on the Wait screen. When outputting a print job for Direct Print and such without temporarily saving it, input the job in Wait mode; you can set the automatic inspection. This option is displayed when Auto Inspection Unit UK-301 is mounted. | Yes, No | |

Reference Image Automatic Deletion | Configure a setting to automatically delete the reference image that is created for automatic inspection. When the amount of available reference image memory is not sufficient, the reference image of the oldest update date and time in Reference Image List 1 is deleted automatically. This option is displayed when Auto Inspection Unit UK-301 is mounted. | ON, OFF | |

* When Image Controller IC-313, Image Controller IC-314, or Image Controller IC-417 is installed on the machine, Level Setting is displayed. Select Essential, Standard, or Premium to specify the level for each item.

NOTICE

Reference Image Automatic Deletion is set to ON by default. When you do not want to automatically delete a reference image, set to OFF.

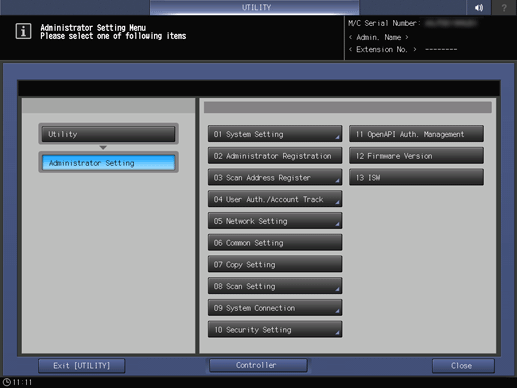

Follow the procedure shown in Displaying the Administrator Setting Menu Screen to display the Administrator Setting Menu screen.

Press Common Setting on the Administrator Setting Menu screen.

The Common Setting screen is displayed.

supplementary explanationFor subsequent operations, follow the same procedure as that in User Setting - Common Setting. Refer to User Setting: Common Setting for details.