Correcting Unevenness and Improving Feedability (Outputting with Fixing Unit and Adjusting Conveyance Performance)

The output image may show unevenness when the original (data) having a high proportion of texts and photos is printed on large-sized paper.

This unevenness shown on paper sizes larger than 8.5 11 short edge feed/long edge feed or A4 short edge feed/long edge feed can be corrected by operating compression adjusting lever of the fixing unit mounted on the main body.

If feedability decreases when printing small-sized thick paper (smaller than 200 mm / 7.87" in the feed direction) or coated thin paper (smaller than 100 g/m2 / 27 lb Bond), you can improve the feedability by increasing the compression in the fixing unit mounted on the main body.

Follow the procedure below to adjust the compression in the fixing unit.

preconditionCorrectable paper sizes are A4 short edge feed/long edge feed, 8.5 11 short edge feed/long edge feed or larger. Do not operate the compression adjusting lever of the fusing device when using paper sizes smaller than these sizes.

NOTICE

Do not move the compression adjusting lever for any purposes other than this adjustment. Also, always set the compression adjusting lever to the triangle position in the center.

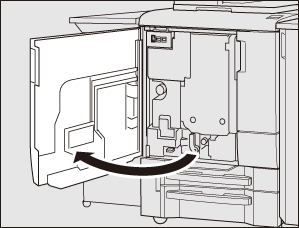

Open the machine front door.

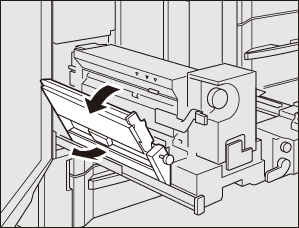

Turn down the lever [M1] leftward, then withdraw the conveyance fusing unit.

Push up the lever [M6], then open the left cover of the fusing unit leftward.

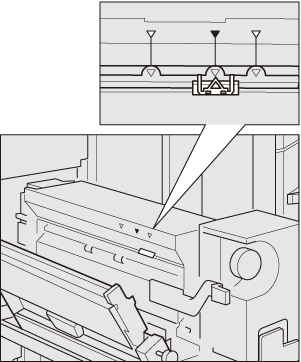

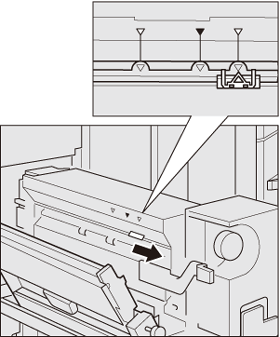

To correct the unevenness in output images on large-sized paper, slide the compression adjusting lever to the right side to align it to the right triangle position.

To improve feedability when printing small-sized thick paper or coated thin paper, slide the compression adjusting lever to the left side to align it to the left triangle position.

Return the left cover of the fixing unit to its original position. Return the conveyance fusing unit to its original position, then reset the lever [M1].

Close the main body front door.