Sequential Checking of Barcode and Serial No. Areas

Overview

You can check whether serial numbers and barcodes in areas to which a barcode inspection or serial number inspection is applied are changing correctly. This section describes how to configure those settings.

Assumed Operating Environment

Item Name | Contents |

|---|---|

OS | Windows 10 |

Application | Adobe Acrobat Reader DC |

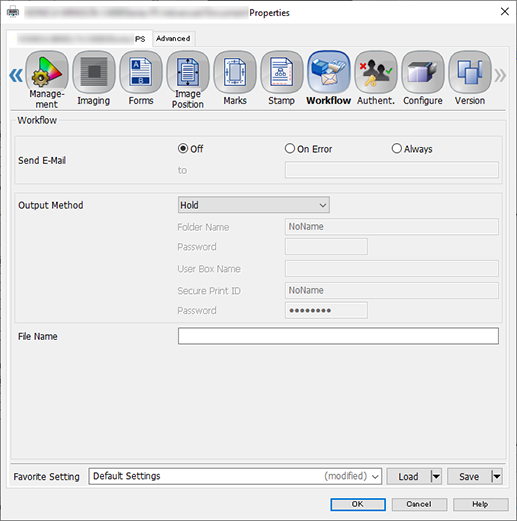

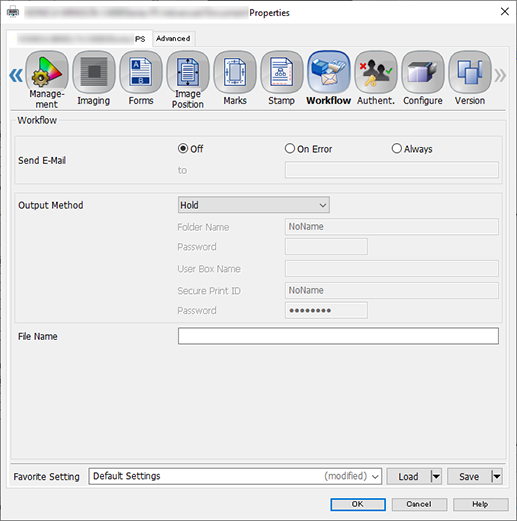

Printer Driver | PS Plug-in Driver |

Option | Image Controller Intelligent Quality Care Unit IQ-501 Auto Inspection Unit UK-301 Relay Unit RU-702 Video Interface Kit VI-514 Video Interface Kit VI-515 |

- The displaying of inspection results for [Barcode Area] or [Serial No. Area] is optional. These functions are not displayed by default. To use this setting, please contact your service representative.

- When setting up the printer driver, make sure you check that none of the previous settings are left in any of the item tabs. If any of the previous settings do remain, make sure you clear them.

Setting Procedure

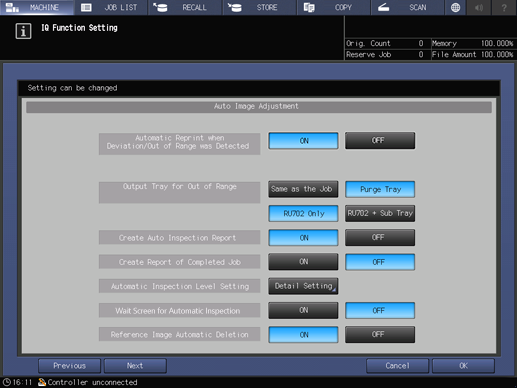

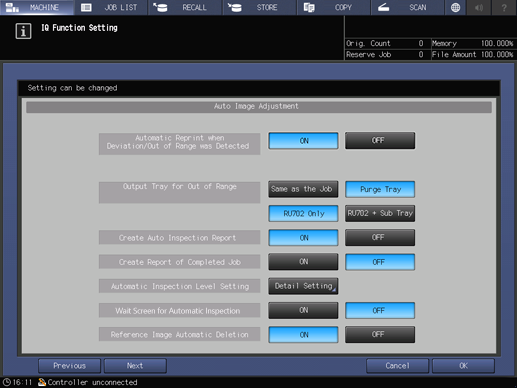

You can also configure this setting by accessing Utility/Counter, [User Setting], and then [Common Setting], or Utility/Counter, [Administrator Setting], and then [Common Setting].

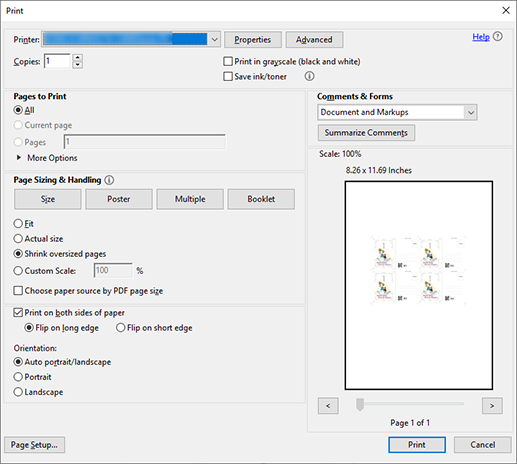

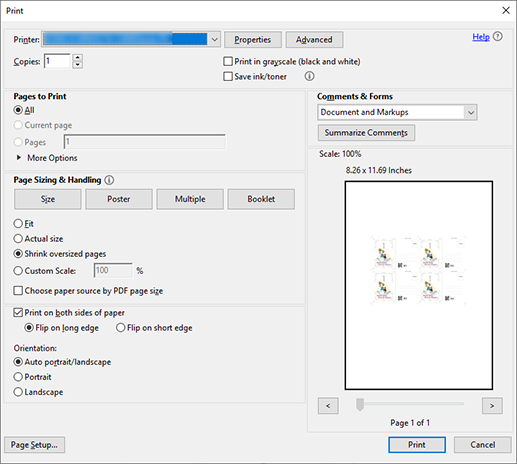

This section describes the procedure for holding a job using the PS Plug-in Driver and configuring the settings using system’s Touch panel.

You can perform the same operation using Print Manager.

For example, a single reference set is selected from [Printing Pages] in the [General] tab, and printed as proof.

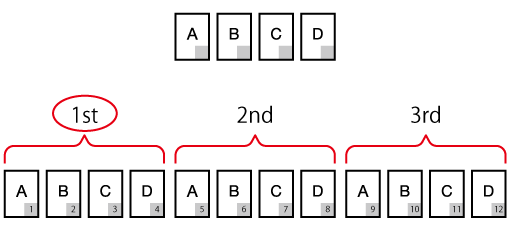

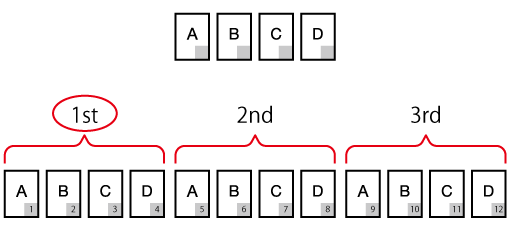

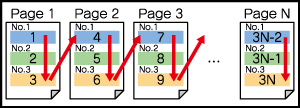

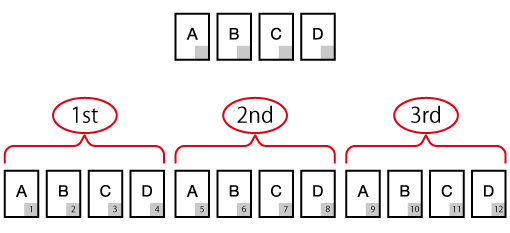

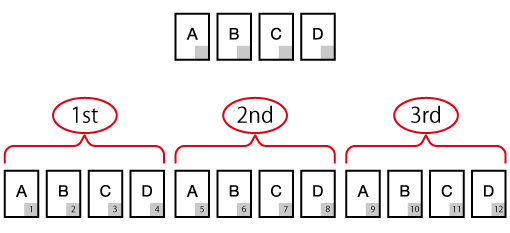

The diagram shows that if there are 12 sheets in the variable job, inspection will be carried out 3 times; once for every 4 reference images (A, B, C, D). The number of inspections will be repeated depending on the number of sheets in the given job. (A to D: Reference image, Gray part: Variable area)

If necessary, check for any abnormalities in the output paper that was proof printed as a reference image. If you want to recreate a reference image, repeat Step 1 through Step 11.

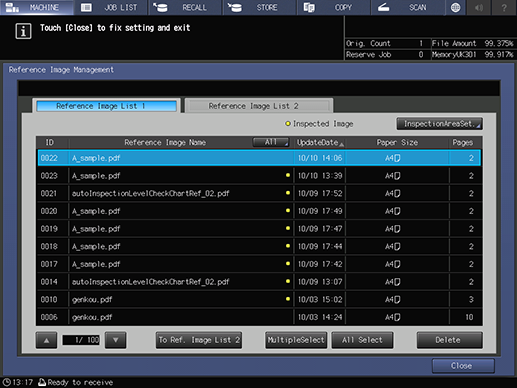

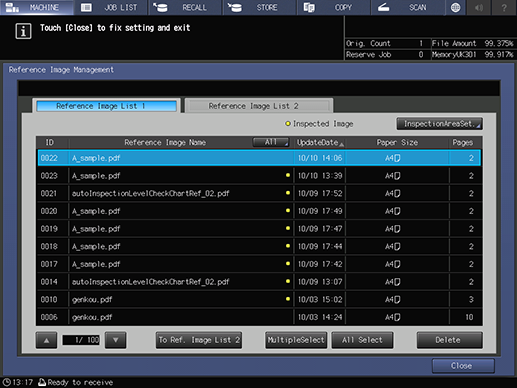

After successfully printing the proof copy, the printed data is registered as a reference image. The reference image has the same file name as the original.

The printed data is also registered and displayed as a reference image on the [MACHINE] and [Reference Image Management] screens on the system’s Touch panel, as well as in [Reference Image List 1]. For details, refer to [Ref. Image Manage.].

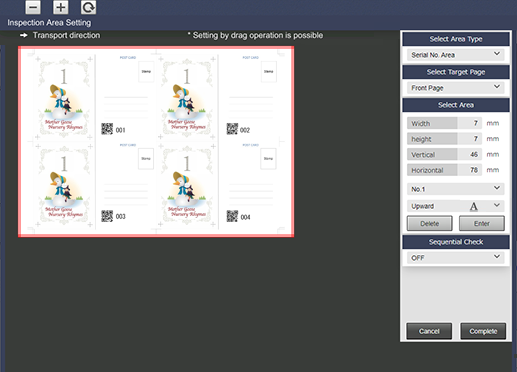

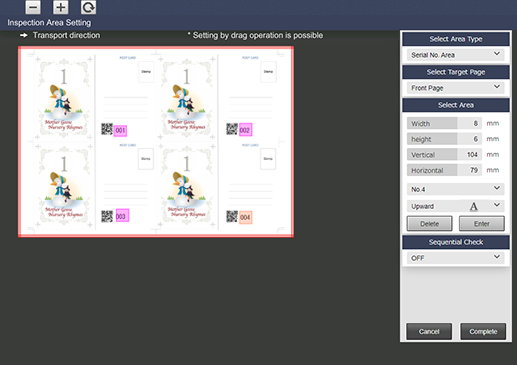

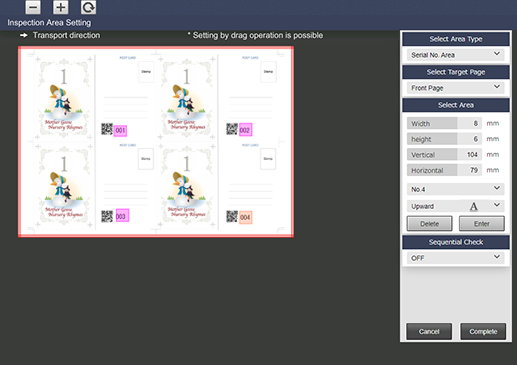

The [Inspection Area Setting] screen is displayed.

For details about the settings, refer to the settings on the [Inspection Area Setting] screen (described after the procedure).

For details about the settings, refer to the settings 1 in the [Sequential Check] (described after the procedure).

You can check the decoding results (CSV file) from the automatic inspection report.

In this example, the print job, including all repeat parts are printed from [Printing Pages] in the [General] tab.

Perform Step 1 through Step 5 from Checking Automatic Inspection Reports Using the Browser.

For details about the settings, refer to the settings 2 in the [Sequential Check] (described after the procedure).

- For details about inspection areas and sequential checks, refer to [InspectionAreaSet.].

Settings on the [Inspection Area Setting] screen

Step No. | Item | Setting Value |

|---|---|---|

1 | [Select Area Type] | For example, select [Serial No. Area] |

2 | [Select Target Page] | Select the side to which the inspection area settings will be applied However, if you set [Select Page], you will not be able to set [Front Page] and [Back Page]. |

3 | [Select Area] | Set the area for the side selected in Step 2 Input the respective values. Alternatively, drag the mouse cursor to specify an inspection area. Press [Enter] to finish configuring the inspection area settings. |

4 | [No.1] to [No.30] | To set 2 or more [Select Area], select [No.2] (or the relevant quantity) from the menu list and repeat Step 3 You can set up to 30 for both [Front Page] and [Back Page]. If you want to delete the settings, select the number you want to delete, and press [Delete]. |

Setting details 1 of [Sequential Check]

Item | Description |

|---|---|

[Check the data inside a page] | Check that ordered numbers on the page are changing correctly according to the area number. Area numbers do not need to be consecutive. In the event of Area No. 1, Area No. 2, Area No. 4 (no Area No. 3), the Area No. 3 check will not be performed, but Area No. 1, Area No. 2 and No. 4 will be performed in that order. |

[Check the data between pages] | Check that the numbers set for each area number are changing correctly between pages. |

- If you set [Check the data inside a page] or [Check the data between pages] in [Sequential Check], you can set whether to perform sequential checks for each area number. For details, refer to [Barcode Area] / [Serial No. Area].

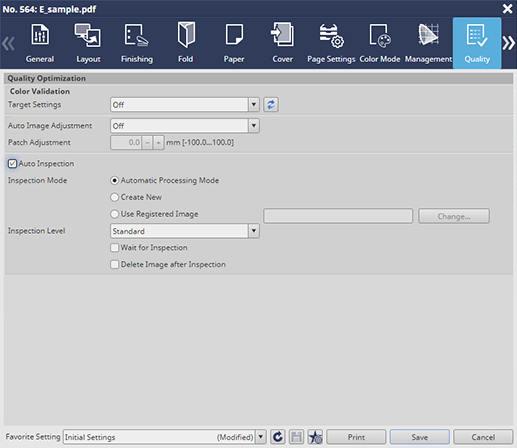

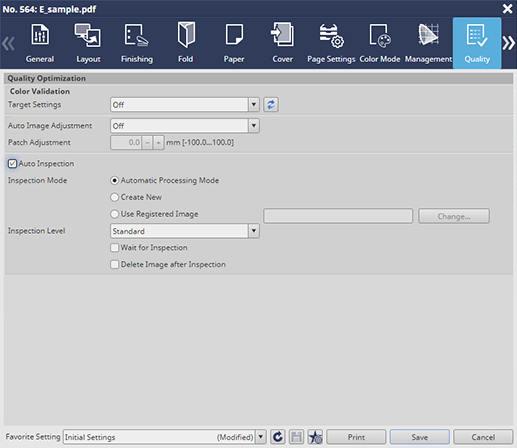

[Quality] tab settings

Item | Setting Value |

|---|---|

[Inspection Mode] | Select reference images for which the inspection area has been set |

[Inspection Level] | For example, select [Standard] |

Setting details 2 of [Sequential Check]

No. | Item | Check Items |

|---|---|---|

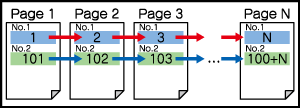

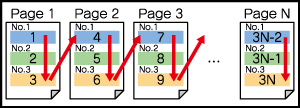

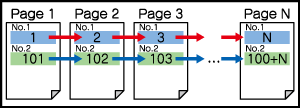

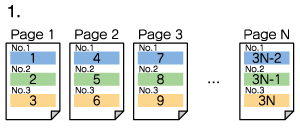

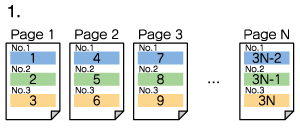

1 | [Check the data inside a page] | Check that the decoding results for the area number are arranged properly. Check that the decoding results for the final area number on the current page, and the decoding results for the first area number on the next page are arranged properly. For example, in the case of sheet number 1 and sheet number 2 shown in Figure 1, since the decoding results for Area No. 3 on sheet 1, and Area No. 1 on sheet 2 are arranged as 3, 4, there would be no problem. |

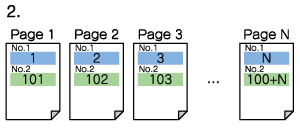

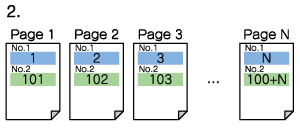

2 | [Check the data between pages] | Check that the decoding results for each area number are arranged sequentially between the paper sheets. In the example used in Figure 2, the decoding results for Area No. 1 across the pages are arranged correctly as 1, 2, 3, and so there is no problem. Next, check the same for Area No. 2. In this case, the decoding results are arranged correctly as 101, 102, 103, and so there is no problem. |

in the upper-right of a page, it turns into

in the upper-right of a page, it turns into  and is registered as a bookmark.

and is registered as a bookmark.