Perfect Binder PB-503

Name and Function of Each Component

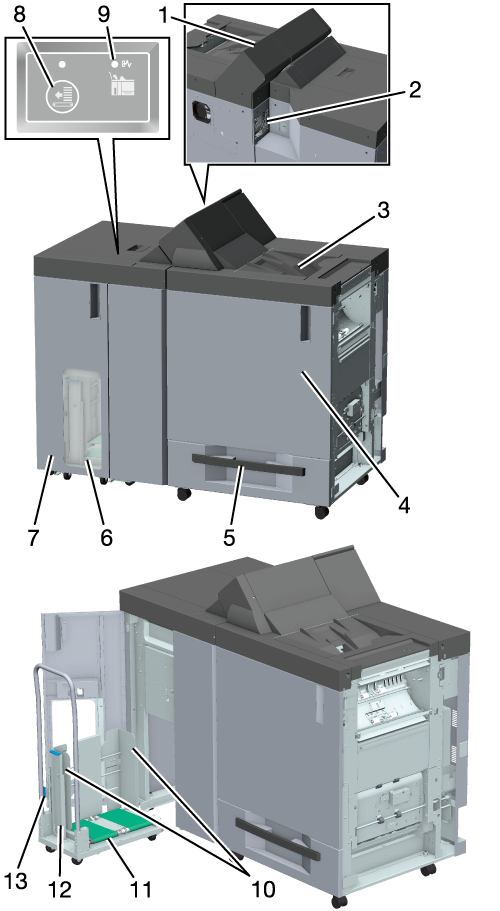

Perfect Binder PB-503 external

No. | Name | Description |

|---|---|---|

1 | Glue hopper cover | Open this cover when replenishing glue pellet. |

2 | Exhaust fan | Discharges Perfect Binder PB-503 exhaust. |

3 | Secondary (sub) tray | Ejects paper without processing in Perfect Binder PB-503. |

4 | Perfect binder tray front door | Open this door when clearing paper jams or trim scraps. When you open the Perfect binder tray front door, you will see that the glue tank unit is attached in the back. |

5 | Cover tray | Stores bookbinding cover. |

6 | Perfect binder tray window | Used to check the stacked paper in the bookbinding tray. When paper is stacked on the right side of the bookbinding tray, press Feeding button to feed out paper to the Carriage. |

7 | Perfect binder tray front door | Open this door when removing bound paper. |

8 | Feeding button | Press this button when feeding out the bound paper to the Carriage. |

9 | Paper jam indicator | Lights up when a paper jam occurred in the paper conveyed by the Perfect Binder PB-503 finisher. |

Perfect binder tray front door internal

No. | Name | Description |

|---|---|---|

10 | Book holding plate | Place this plate along the stacked bound paper to prevent the paper from collapsing when moving the Carriage. |

11 | Carriage | Used to carry the bound paper from the Perfect Binder PB-503. |

12 | Book stopper | Inserting in the optional stopper positioning hole prevents paper from collapsing when moving the Carriage. |

13 | Book holding plate lever | Move this lever when lining up the Book holding plate along paper. |

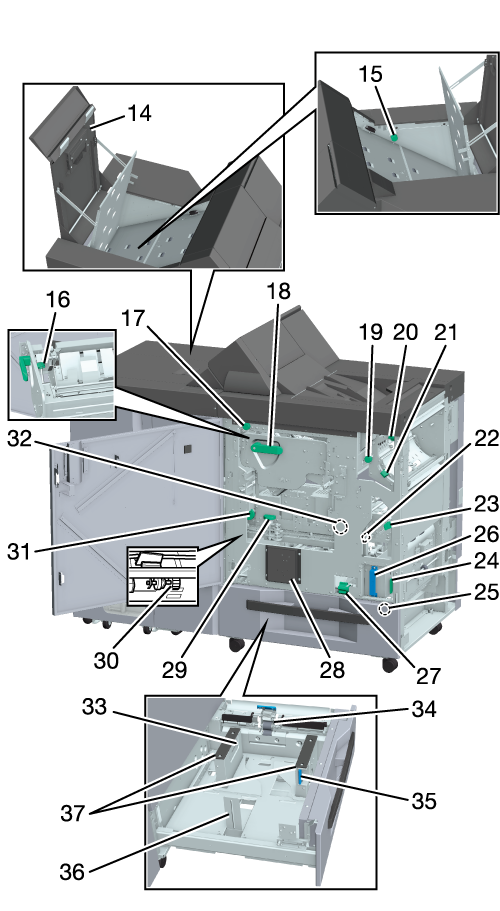

Conveyance section

No. | Name | Description |

|---|---|---|

14 | Conveyance section cover | Open this cover to clear a paper jam when Paper jam indicator lights up. |

15 | Knob [PB14] | When clearing a paper jam, turn the knob counterclockwise to feed the paper through. |

Perfect binder tray front door internal

No. | Name | Description |

|---|---|---|

16 | Body set release knob in clamp unit | When removing the body paper fixed to the clamp unit, turn the knob clockwise. |

17 | Knob [PB2] | When clearing a paper jam, turn the knob to feed the body paper to the clamp unit. |

18 | Lever [PB7] | When removing the body paper jammed in the clamp unit, press this lever downward and pull out the paper. |

19 | Knob [PB6] | When clearing a paper jam, turn the knob to feed out the paper to the Secondary (sub) tray. |

20 | Lever [PB3] | When clearing a paper jam, hold the lever, open the guide, and remove the body paper. |

21 | Lever [PB1] | When clearing a paper jam, hold the lever, open the guide, and remove the body paper. |

22 | Lever [PB12] | When clearing a paper jam, hold the lever, open the guide, and remove the body paper. |

23 | Lever [PB4] | When clearing a paper jam, hold the lever, open the guide, and remove the cover. |

24 | Lever [PB5] | When clearing a paper jam, pull out the Trim scrap box, open it leftward, and remove the cover. |

25 | Knob [PB13] | When clearing a paper jam, turn the knob clockwise to feed the cover through. |

26 | Trim scrap box | Pull out this box to discard trim scraps. |

27 | Knob [PB11] | When clearing a paper jam, turn this knob upward; the binding unit lowers. |

28 | Jam position display | The location of the paper jam is indicated by a LED light. |

29 | Knob [PB8] | When clearing a paper jam, turn the knob clockwise, and remove the cover from the binding unit. |

30 | Binding unit release knob | When clearing a paper jam, turn this knob downward to remove the cover from the binding unit that remains elevated. |

31 | Knob [PB9] | When clearing a paper jam, turn the knob clockwise to release the cover fixing plate. |

32 | Knob [PB10] | When clearing a paper jam, turn the knob counterclockwise to release the cover fixing plate. |

Cover tray internal

No. | Name | Description |

|---|---|---|

33 | Air nozzle | Blows air to prevent the same cover from being fed multiple times. |

34 | Feed roller | Feeds sheets into the Perfect Binder PB-503 one by one. |

35 | Lock release knob | When moving the Guide plates, push this knob to the back to unlock. |

36 | Rear stopper | Align this guide with the rear edge side of the loaded paper. |

37 | Guide plates | Align this guide with both sides of the loaded paper. |

Specifications

Name | Perfect Binder PB-503 | |

Type | Perfect binding with the console hot melting system | |

Function | Perfect Binding | After automatic perfect binding, ejected to Perfect binder tray. |

Secondary (sub) tray | Ejects to Secondary (sub) tray without processing. | |

Relay conveyance | Conveys paper to post-processing device without processing. | |

Number of bound sheets | 10 to 300 sheets, or within 30 mm / 1.18" thickness Maximum 150 sheets or thickness of up to 15 mm / 0.59" for color paper or coated paper (ML, MO) The maximum number of sheets for Z-fold is 4 sheets or less for double-sided printing and 2 sheets or less for single-side printing. | |

Paper size | Perfect binder tray |

Standard: A4 v, B5 v, A5 w/v, 8.5 e 11 v, 5.5 e 8.5 w/v, 16K v Custom: Widthwise 139 mm to 307 mm, lengthwise 210 mm to 221 mm / Widthwise 5.47" to 12.09", lengthwise 8.27" to 8.7"

Widthwise 139 mm to 307 mm, lengthwise 279 mm to 472 mm / Widthwise 5.47" to 12.09", lengthwise 10.98" to 18.58" |

Secondary (sub) tray | Standard: SRA3 w, A3 w, B4 w, SRA4 w/v, A4 w/v, B5 w/v, A5 w/v, B6 w, A6 w, Postcard w*1, 13 e 19 w, 12 e 18 w, 11 e 17 w, 9 e 11 v, 8.5 e 14 w, 8.5 e 11 w/v, 7.25 e 10.5 w/v, 5.5 e 8.5 w/v, Foolscap*2, 8K w, 16K w/v Custom: Widthwise 95 mm to 331 mm, lengthwise 139 mm to 488 mm / Widthwise 3.74" to 13.03", lengthwise 5.47" to 19.21" Tab paper: A4T v, 8.5 e 11T v *1: Only in Japan. *2: Foolscap refers to 8.5 e 13 w, 8.25 e 13 w, 8.12 e 13.25 w, and 8 e 13 w sizes. | |

Paper weight | Perfect binder tray | Body: 64 g/m2 to 105 g/m2 / 17 lb Bond to 28 lb Bond Cover: 81 g/m2 to 216 g/m2 / 22 lb Bond to 57 lb Bond |

Secondary (sub) tray | 40 g/m2 to 400 g/m2 / 10 lb Bond to 106 lb Bond * The paper type is limited to 351 g/m2 to 400 g/m2 / 94 lb Bond to 106 lb Bond. | |

Paper type | Perfect binder tray | Body: Plain, Fine, Color Specific, Coated-ML, Coated-MO Cover: Fine, Coated |

Secondary (sub) tray | All types of paper used in the machine | |

Tray capacity | Cover tray | 1,000 sheets (82 g/m2 / 23 lb Bond) 500 sheets (216 g/m2 / 57 lb Bond) |

Perfect binder tray | For booklets with maximum thickness of 30 mm / 1.18" (approx. 300 sheets), 11 booklets e 2 columns (equivalent to approximately 6,600 sheets). Set capacity is as follows, according to number of sheets in body. 10 to 30 sheet booklet: 50 sets, 31 to 150 sheet booklet: 35 sets or up to maximum detection, 151 to 300 sheet booklet: Up to maximum detection | |

Secondary (sub) tray | Approx. 200 sheets (80 g/m2 / 21 lb Bond) (includes full detection) | |

Cover cutting | Select whether to include/not include cutting. | |

Warm-up time | Approx. 20 minutes | |

Dimensions | 1,360 mm (W) e 708 mm (D) e 1,223 mm (H) / 53.54" (W) e 27.87" (D) e 48.15" (H) | |

Weight | Approx. 270 kg / 595.25 lb | |

Power | In Japan: AC 100 V, 50/60Hz (supplied from power cord) Metric area: AC 230 V, 50 Hz (supplied from power cord) Inch area: AC 120 V, 60 Hz (supplied from power cord) DC 24 V, 5 V (partially supplied from the front stage) | |

Maximum power consumption | 1,000 W or less | |

in the upper-right of a page, it turns into

in the upper-right of a page, it turns into  and is registered as a bookmark.

and is registered as a bookmark.