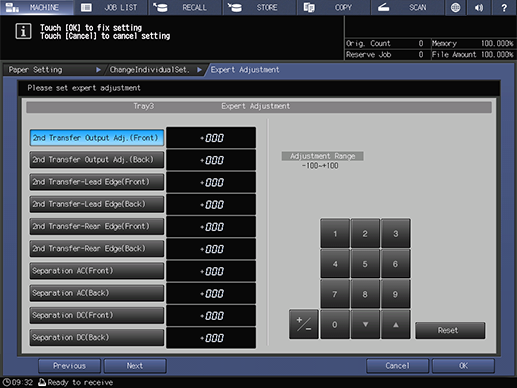

[Expert Adj.]

Overview

Set the advanced adjustment items such as the transfer, separation, or fusing process.

Adjusting the [Expert Adj.] items allows you to deal with various situations or finishing conditions.

- The selectable items vary depending on the optional devices mounted on this system.

Setting Items

Setting item | Description |

|---|---|

[2nd Transfer Output Adj.(Front)] | Set the adjustment range when a deficient transfer or white spots occur on the front side of paper. Range: -100 to +100 |

[2nd Transfer Output Adj.(Back)] | Set the adjustment range when a deficient transfer or white spots occur on the back side of paper. Range: -100 to +100 |

[2nd Transfer-Lead Edge(Front)] | Set the adjustment range when a deficient transfer occurs at the lead edge of the front side of paper. Range: -100 to +100 |

[2nd Transfer-Lead Edge(Back)] | Set the adjustment range when a deficient transfer occurs at the lead edge of the back side of paper. Range: -100 to +100 |

[2nd Transfer-Rear Edge(Front)] | Set the adjustment range when a deficient transfer or transfer repelling occurs at the rear edge of the front side of paper. Range: -100 to +100 |

[2nd Transfer-Rear Edge(Back)] | Set the adjustment range when a deficient transfer or transfer repelling occurs at the rear edge of the back side of paper. Range: -100 to +100 |

[Separation AC(Front)] | Set the adjustment range when a transfer leak mark or electrostatic noise occurs while printing the front side. Range: -50 to +50 |

[Separation AC(Back)] | Set the adjustment range when a transfer leak mark or electrostatic noise occurs while printing the back side. Range: -50 to +50 |

[Separation DC(Front)] | Set the adjustment range when an offset occurs while printing the front side. Range: -30 to +30 |

[Separation DC(Back)] | Set the adjustment range when an offset occurs while printing the back side. Range: -30 to +30 |

[Fus.T-Belt Center Temp.(Idle)] | Set the adjustment range when a curl or a paper wrapping jam (fusing belt) occurs. Set a difference between the following setting item values to less than 10. Setting to 10 or more may result in system warm up taking longer.

Range: -20 to +20 |

[Fus.T-Belt Center Temp.(Print)] | Set the adjustment range when one of the following phenomena occurs.

Set a difference between the following setting item values to less than 10. Setting to 10 or more may result in system warm up taking longer.

Range: -20 to +20 |

[Fus.T-Belt Edge Temp.(Idle)] | Set the adjustment range when a paper jam caused by a curl or paper wrapping (fusing belt) occurs. Set a difference between the following setting item values to less than 10. Setting to 10 or more may result in system warm up taking longer.

Range: -20 to +20 |

[Fus.T-Belt Edge Temp.(Print)] | Set the adjustment range when one of the following phenomena occurs.

Set a difference between the following setting item values to less than 10. Setting to 10 or more may result in system warm up taking longer.

Range: -20 to +20 |

[L-Fus. Press Roller Center(Idle)] | Set the adjustment range when one of the following phenomena occurs.

Range: -20 to +20 |

[L-Fus. PressRoller Center(Print)] | Set the adjustment range when one of the following phenomena occurs.

Range: -20 to +20 |

[Lead Edge Erase Quantity] | Set the adjustment range when a separation defection (fusing belt) occurs on thin paper (low stiffness paper). Range: 0 to +200 |

[Rear Edge Erase Quantity] | Set the adjustment range when a separation defection (fusing belt) occurs on thin paper (low stiffness paper). Range: 0 to +200 |

[Registration Loop(Front)] | Set the adjustment range when paper wrinkles or paper jams in the registration roller section occur while printing the front side of thin paper (low stiffness paper). Range: -99 to +99 |

[Registration Loop(Back)] | Set the adjustment range when paper wrinkles or paper jams in the registration roller section occur while printing the back side of thin paper (low stiffness paper). Range: -99 to +99 |

[IQ Transport Roller Speed Adj.] | If a crease or delivery failure occurs while thin paper (low stiffness paper) is scanned on Intelligent Quality Care Unit IQ-501, set the speed balance of the conveyance roller. Range: 0 to +20 |

[Fusing Speed(Front Side)] | Set the adjustment range when one of the following phenomena occurs.

|

If a failure occurs on both the front and back sides, first perform the fusing speed adjustment (front side), and then perform the fusing speed adjustment (back side offset). Range: -200 to +200 | |

[Fusing Speed(Back Side Offset)] | Set the adjustment range when one of the following phenomena occurs.

|

If a failure occurs on both the front and back sides, first perform the fusing speed adjustment (front side), and then perform the fusing speed adjustment (back side offset). Range: -200 to +200 | |

[Registration Roller Speed] | Set the adjustment range when a transfer slippage or color gap occurs.

Range: -10 to +10 |

[Pre-regist. Loop Adj.(Front)] | Set the adjustment range when one of the following phenomena occurs on the front side of the paper.

Range: -99 to +99 |

[2nd Transfer Belt Speed] | Set the adjustment range when a minute transfer slippage occurs on the whole surface of paper. Range: -50 to +60 |

[Pre-regist.Loop:1st Connection]*1 | Set the adjustment range when one of the following phenomena occurs on the front side of the paper.

Range: -99 to +99 |

[Pre-regist.Loop:2nd Connection] | Set the adjustment range when one of the following phenomena occurs on the front side of the paper.

The following option is required to use this function.

Range: -99 to +99 |

[Pre-regist.Loop:BypassConnection] | Set the adjustment range when one of the following phenomena occurs on the front side of the paper.

The following option is required to use this function.

Range: -99 to +99 |

[Pre-regist.Loop:ADU Reverse Part] | Set the adjustment range when crescent shaped fold or curved paper occurs at the following positions while 2-sided printing.

Range: -99 to +99 |

[Pre-regist.Loop:ADU Exit Part] | Set the adjustment range when a paper skew occurs on the back side while 2-sided printing. Range: -99 to +99 |

[LeadEdgeSlightPress.StartTiming] | Set the adjustment range when an image jitter occurs on thick paper.

Range: -10 to +10 |

[Lead Edge Crimping Start Timing] | Set the adjustment range when an image jitter occurs on thick paper.

Range: -10 to +10 |

[RearEdgeSlightPress.StartTiming] | Set the adjustment range when an image jitter occurs on thick paper.

Range: -10 to +10 |

[Rear Edge Crimping Start Timing] | Set the adjustment range when an image jitter occurs on thick paper.

Range: -10 to +10 |

[Lead Edge Slight Pressure Amount] | Set the adjustment range when an image jitter occurs on thick paper.

Range: -10 to +10 |

[Rear Edge Slight Pressure Amount] | Set the adjustment range when an image jitter occurs on thick paper.

Range: -5 to +5 |

[Paper Cooling Air Level] | Set the adjustment range when paper wrinkles occur at the lead edge during 2-sided printing of thin paper (low stiffness paper). Range: -100 to 0 |

[Main Body De-Curler Speed] | Set the adjustment range when buckling jams occur near the de-curler roller of the reversing unit during 2-sided printing of thin paper (low stiffness paper). Range: -30 to +30 |

[Toner Amount Save] | Set this when a separation defection (fusing belt) occurs on thin paper (low stiffness paper).

[ON]: Controls the total toner consumption. [OFF]: Does not control the total toner consumption. |

[Dens. Adj. Per Tray(YMC)] | Set this option when the image density (YMC) is low on uncoated paper such as plain paper, rough paper, and textured paper. [0(Normal)]: Sets to the standard density. [+1] to [+3(Max)]: Sets the density to a positive "+" value than the standard. |

[Dens. Adj. Per Tray(K)] | Set this option when the image density (K) is low on uncoated paper such as plain paper, rough paper, and textured paper. [0(Normal)]: Sets to the standard density. [+1] to [+3(Max)]: Sets the density to a positive "+" value than the standard. |

[Double Feed Detection]*1 | Configure the setting to detect double feeding. [Detect]: Detects double feeding. [Not Detect]: Does not detect double feeding. |

[Mis-centering Detect JAM] | Configure the setting to detect mis-centering of 5 mm / 0.2" or more as a paper jam. [Detect]: Detects mis-centering. [Not Detect]: Does not detect mis-centering. |

[Int. Transfer Separation] | Set this option when white lines occur in the halftone image of the original. [Auto]: Automatically performs intermediate transfer separation. [ON]: Performs intermediate transfer separation. [OFF]: Does not perform intermediate transfer separation. |

[ADU Reverse Pre-regist] | Set this function when damage occurs at the paper lead edge during 2-sided printing of thin paper (low stiffness paper). When [Auto] or [ON] is set, if damage occurs at the paper lead edge of the back side, set to [OFF]. However, if [OFF] is set, the paper skew adjustment may be affected. [Auto]: Automatically performs ADU Reverse Pre-regist. [ON]: Performs ADU Reverse Pre-regist. [OFF]: Does not perform ADU Reverse Pre-regist. |

[Feed Correction] | Configure this setting when curving occurs at the position (end of the registration roller position) within 118 mm / 4.65" before/after the center of thick paper (high stiffness paper). [ON]: Enables [Feed Correction]. [OFF]: Disables [Feed Correction]. |

[Lower Fusing Roller Cooling Fan Air Level] | Set this when a blur occurs on thin paper (low stiffness paper). [Standard]: Sets the cooling fan air level to Standard. [Weak]: Sets the cooling fan air level to Weak. [OFF]: Turns the cooling fan air volume off. |

[Main Body Curl Adj.] | Set this when one of the following phenomena occurs while 2-sided printing.

[Auto]: Automatically adjusts the machine curling level. [Weak]: Adjusts the machine curling level to be weaker than [Normal]. [Normal]: Adjusts the machine curling level to the standard. [Strong]: Adjusts the machine curling level to stronger than [Normal]. |

[2nd Transfer High Speed Crimping/Spacing Set.] | Set this when a transfer deficiency (spots, etc.) occurs at the lead and rear edges of paper. However,image jitter (shock noise) may get worse at the position set to OFF. [Lead/Rear:ON]: Sets the 2nd transfer high speed crimping/spacing position to the lead/rear edge of paper. [Lead/Rear:OFF]: Does not set the 2nd transfer high speed crimping/spacing position to the lead/rear edge of paper. [Lead:ON/Rear:OFF]: Sets the 2nd transfer high speed crimping/spacing position only to the lead edge of paper. [Lead:OFF/Rear:ON]: Sets the 2nd transfer high speed crimping/spacing position only to the rear edge of paper. |

[PaperCoolLowerFanLevel]*1 | Set to [ON] when wavy wrinkles occur in the center of the lead edge during 2-sided printing on thin paper. [Auto]: Automatically switches the paper cooling air level. [ON]: Enables the paper cooling air level. [OFF]: Disables the paper cooling air level. |

[Real Time Centering Adj.] | Set this when creases or end of image bending occurs. [ON]: Performs centering adjustment in real time. [OFF]: Does not perform centering adjustment in real time. |

[1st Trans.Press.Switch] | If transcription is low on paper with a rough surface, set to [Textured]. If an image jitter occurs on textured paper, set to Normal Mode. [Auto]: Automatically switches the transfer pressure level. [Not Textured]: Switches the transfer pressure level to the standard. [Textured]: Automatically switches the transfer pressure level to for textured paper. |

[2nd Trans.Press.Switch] | Configure the setting to suit the paper loaded in the paper tray when one of the following phenomena occurs.

[Auto]: Automatically switches the transfer pressure level. [1]: Sets the transfer pressure level to the standard. [2]: Sets the transfer pressure level to be stronger than the standard. |

[2nd Transfer Separate Timing:Front] | Select the level when paper wrapping around the intermediate transfer belt or the 2nd transfer belt occurs while printing the front side in thin paper feeding mode.

[Auto]: Automatically switches the separation bias timing of the front side. This system automatically controls the loss amount of the image at the lead edge depending on the paper type or paper weight. [OFF]: Does not automatically switch the separation bias timing of the front side. The loss amount of the image at the lead edge is fixed to 0 mm / 0" regardless of the paper type or paper weight. [1] to [7]: Select the separation bias timing level of the front side. |

[2nd Transfer Separate Timing:Back] | Select the level when paper wrapping around the intermediate transfer belt or the 2nd transfer belt occurs while printing the back side in thin paper feeding mode.

[Auto]: Automatically switches the separation bias timing of the back side. This system automatically controls the loss amount of the image at the lead edge depending on the paper type or paper weight. [OFF]: Does not automatically switch the separation bias timing of the back side. The loss amount of the image at the lead edge is fixed to 0 mm / 0" regardless of the paper type or paper weight. [1] to [7]: Select the separation bias timing level of the back side. |

[Centering Adj.(Front)] | Set this when you want to offset the image position on the front side. |

[ON(Blank)]: Select this item when the paper color is white. This function adjusts mis-centering on the front side of paper. [ON(PrePrinted)]: Select this option when performing PrePrinted. [OFF]: Does not make adjustment. | |

[Detect Setting]: Adjusts the mis-centering detection position when PrePrinted is selected. [(1)Detect Range]: Sets the range without a rough sketch. Range: 1 mm to 10 mm | |

[PaperColor(Light)]: Select this item when the paper color is white or pale. [PaperColor(Dark)]: Select this item when the paper color is dark. | |

[Centering Adj.(Back)] | Set this when you want to offset the image position on the back side. |

[ON(Blank)]: Select this item when the paper color is white. This function adjusts mis-centering on the back side of paper. [ON(PrePrinted)]: Select this option when performing PrePrinted. [OFF]: Does not make adjustment. | |

[Detect Setting]: Adjusts the mis-centering detection position when PrePrinted is selected. [(1)Detect Range]: Sets the range without a rough sketch. Range: 1 mm to 10 mm | |

[PaperColor(Light)]: Select this item when the paper color is white or pale. [PaperColor(Dark)]: Select this item when the paper color is dark. | |

[Fusing Air Separation Air Level Setting] | Set this when a fusing separation failure occurs or when lines in the paper feed direction are caused by the fusing separation claw. [Weak]: Weakens the separation air level each time this key is pressed. [Auto]: Automatically sets the separation air level. [Strong]: Strengthens the separation air level each time this key is pressed. |

[Fusing Cleaning Roller] | Set this when glossy lines occur in the crosswise direction due to residual gloss or margin width. [Auto]: Automatically performs the fusing belt cleaning. [ON]: Enables the fusing belt cleaning. [OFF]: Disables the fusing belt cleaning. |

[FusingNipPressure(Front)] | Set this when one of the following phenomena occurs.

[Auto]: Automatically adjusts the fusing nip pressure. [Standard]: Adjusts the fusing nip pressure to the standard. [Weak]: Adjusts the fusing nip pressure to be weaker than the standard. |

[Envelope Feed: Nip Width] | Set this when creases or stains occur during envelope feeding or when stains occur on the back side after envelope feeding. [Standard]: Automatically adjusts the nip width when feeding envelopes. [-2]: Adjusts the nip width with -2 when feeding envelopes. [-1]: Adjusts the nip width with -1 when feeding envelopes. [+1]: Adjusts the nip width with +1 when feeding envelopes. [+2]: Adjusts the nip width with +2 when feeding envelopes. |

[Thick Paper Fixability] | If this function is set to [ON], the fixability of thick paper is improved. However, the printing speed is slow immediately after the start of printing. It takes about 40 seconds to reach the normal speed. [ON]: Enables [Thick Paper Fixability]. [OFF]: Disables [Thick Paper Fixability]. |

[PFU Suction Air Level Setting]*1 | Set this when a damage occurs on paper due to suction. Lowering the suction air level too much may cause paper jams depending on the paper conditions. [Weak]: Weakens the suction air level each time this key is pressed. [Auto]: Automatically sets the suction air level. [Strong]: Strengthens the suction air level each time this key is pressed. |

[Output Paper Separation Setting] | Set this option when an electrostatic adsorption occurs at the time of output. [ON(Coated)]: Automatically sets the offset (misalignment) amount when coated paper is loaded into a paper tray. [ON(Uncoated)]: Automatically sets the offset amount when paper other than coated paper is loaded into a paper tray. [Manual]: Manually sets the offset amount using [Offset Value]. [OFF]: Offset is not performed. [Offset Value]: Set the offset amount. Adjustment range: -50 to +100 |

[PFU Air Shutter Edge Position Setting] | Set the timing at which to stop air blowing at the PFU edge for floating the edges of the sheets fed from a tray or separating sheets. For thick or thin paper, make adjustment when one of the following phenomena occurs; it may be improved.

|

[Auto]: Automatically adjusts the timing at which to close the air shutter. [Manual]: Manually adjusts the timing at which to close the air shutter. [-1]: Manually advances the timing at which to close the air shutter. [+1]: Manually delays the timing at which to close the air shutter. [+2]: Adjusts the air shutter closing timing to be slower than [+1]. [OFF]: Disables the air shutter. | |

[PFU Paper Float Timing] | Set the timing at which to float paper by air blowing at the PFU lead edge. Some phenomena may be improved by adjustment.

|

[Auto]: Automatically adjusts the paper floating timing. [Manual]: Manually adjusts the paper floating timing. [Earlier]: Advances the paper floating timing. [Delay]: Select [Manual]. Delays the paper floating timing. | |

[PFU Pre-regist Roller Reverse Rotation Control] | If one of the following phenomena occurs; set to None; it may be improved. However, paper skewing may occur.

|

[Auto]: Automatically sets whether to control the reverse rotation of the pre-registered rollers. [Manual]: Manually sets whether to control the reverse rotation of the pre-registered rollers. [Reverse ON] or [Reverse OFF] is selectable. [Reverse ON]: Enables the reverse rotation control of the pre-registered rollers. [Reverse OFF]: Disables the reverse rotation control of the pre-registered rollers. | |

[Thin Paper Setting] | If double feeding occurs when you feed thin paper (52 g/m2 to 61 g/m2 / 14 lb Bond to 15 lb Bond), set to [Thin]; it may be improved. [Normal]: Select this item when double feeding does not occur with thin paper. [Thin]: Select this item when double feeding occurs with thin paper. |

[Auto Inspection Level Detailed Setting]*2 | Adjust the inspection standard for automatic inspection (automatic inspection level). You can set the automatic inspection level for each paper tray. Even if [Enable] is selected, the operation is the same as [Disable] in the following cases.

When there are multiple paper trays to be used when executing a job

|

[Enable]: Sets the automatic inspection level for each paper tray. The paper loaded in the specified paper tray is automatically inspected at the selected level. [Disable]: Disables the automatic inspection level specified for each paper tray. The automatic inspection level specified in [Common Setting] or [IQ Function Setting] is enabled. [Detail Setting]: Set the inspection standard for automatic inspection. Sets the inspection level to suit the selected item. | |

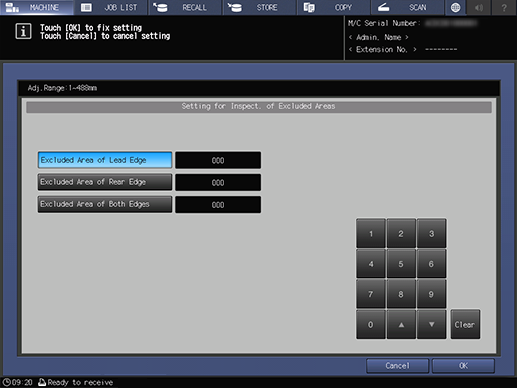

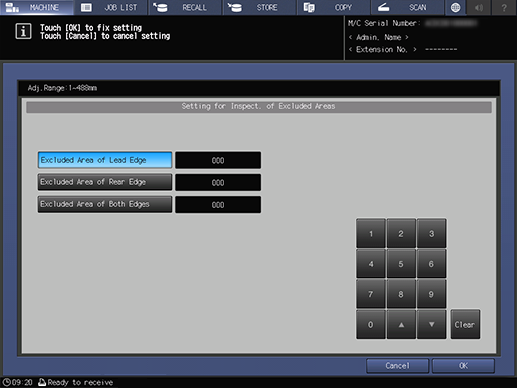

[Excluding Edge Setting for Automatic Inspection]*2 | Set the default Inspection Excluding Area for automatic inspection. You can set the edge exclusion area for each paper tray when generating the reference image. Even if [Enable] is selected, the operation is the same as [Disable] in the following cases.

|

[Enable]: Sets the inspection exclusion area for each paper tray. The set value becomes the edge exclusion area when the reference image is generated. [Disable]: Disables the inspection exclusion area specified for each paper tray. The value specified in [Common Setting] or [Setting for Inspect. of Excluded Areas] of [IQ Function Set.] is enabled. [Detail Setting]: Set the default Inspection Excluding Area for automatic inspection. | |

Keypad | Used to enter numeric values. Press [+ / -], and set the sign of the numeric value. |

*1: One of the following options is required to use this function.

Paper Feeder Unit PF-712

Paper Feeder Unit PF-713

Paper Feeder Unit PF-812

*2: All the following options are required to use this function.

Intelligent Quality Care Unit IQ-501

Auto Inspection Unit UK-301

Relay Unit RU-702

Video Interface Kit VI-514

Video Interface Kit VI-515

Setting Procedure (Adjustment of [Auto Inspection Level Detailed Setting])

For details about the setting procedure, refer to Setting Procedure ([Automatic Inspection Level Setting]).

Setting Procedure (Adjustment of [Excluding Edge Setting for Automatic Inspection])

The setting screen is displayed.

[Adj.Range:1~488mm] 1step=1 mm

in the upper-right of a page, it turns into

in the upper-right of a page, it turns into  and is registered as a bookmark.

and is registered as a bookmark.