Checking the Color Density Control Setting

You can enables the color density control and set the execution timing, etc.

When using the color density control function (Adjustment of color sensor for each paper type / Color density manual control), always set the Use Color Density Control to ON.

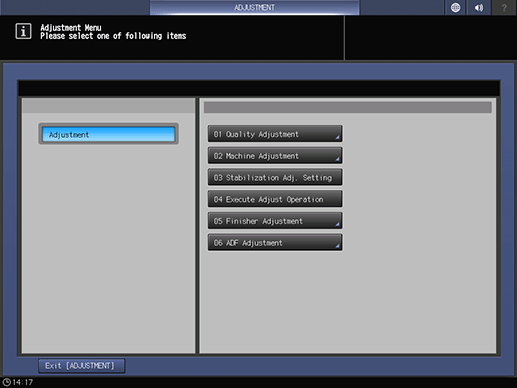

On the touch panel of the main body, press Adjustment on the MACHINE screen.

The Adjustment Menu is displayed.

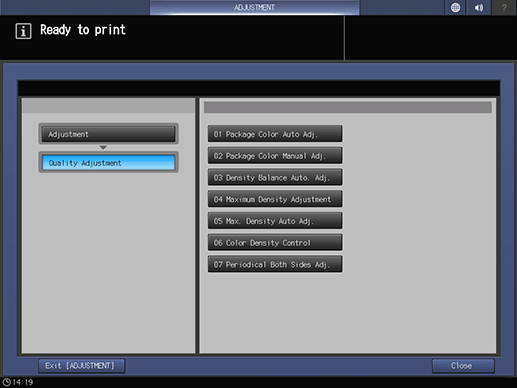

Press Quality Adjustment on the Adjustment Menu.

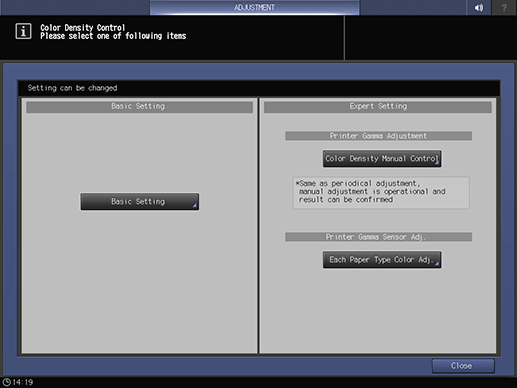

Press Color Density Control.

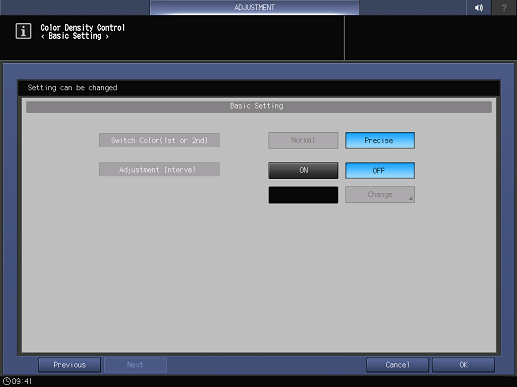

Press Basic Setting.

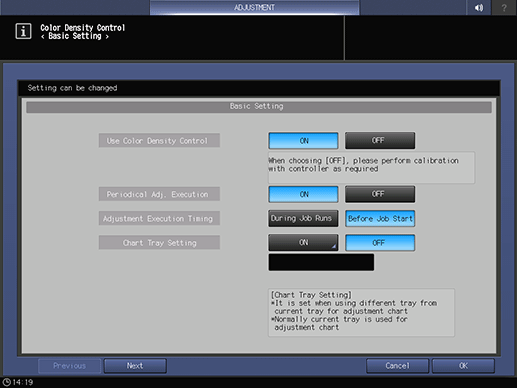

Check that each item is set as shown below.

Item

Description

Use Color Density Control

ON

Periodical Adj. Execution

ON

Adjustment Execution Timing

Before Job Start (Available when you want to prioritize the hue standardization in a single job)

During Job Runs (Available when you want to prioritize the hue standardization among multiple jobs.)

Chart Tray Setting

OFF

supplementary explanationTo periodically perform density adjustment using Relay Unit RU-518 or Integrated Color Care Unit IQ-501, set the Periodical Adj. Execution to ON.

Press Next.

When Integrated Color Care Unit IQ-501 is not mounted on the machine, check that Switch Color(1st or 2nd) is set as shown below as necessary.

supplementary explanationTo prioritize the image quality: Precise

This function adjusts both the primary colors (CMYK) and secondary colors (RGB).

supplementary explanationTo reduce the paper consumption for color density control: Standard

This function only adjusts the primary colors (CMYK).

When Integrated Color Care Unit IQ-501 is mounted on the machine, Precise is always set.

Press OK.

Press Close.

Press Exit [ADJUSTMENT].

The auto adjustment is set up. A chart is printed out periodically, and calibration is executed automatically.