Job Conditions

Overview

Changes to the job conditions impact upon the condition of the system, and can lead to issues during printing.

In order to prevent issues such as image defects, it is necessary to take the appropriate measures according to the job conditions.

This section introduces a range of helpful tips for everyday use, using 3 characteristic job conditions as examples.

Consecutive Printing of Jobs With Different Levels of Coverage

If printing a job with high coverage immediately after printing a high volume of jobs with low coverage, you may find white spots appearing on the image due to image distortion or a build up of toner.

Use "Toner Refresh" to prevent issues caused by coverage fluctuations.

What is Coverage?

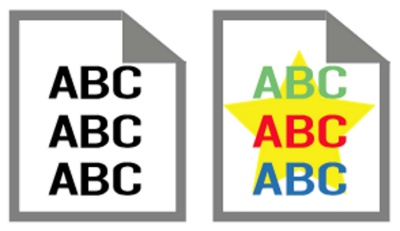

Coverage is the ratio of toner used for a single A4 sheet of paper.

The higher the number of color photographs or illustrations, the higher the coverage. The greater the amount of single color (monochrome) text, the lower the coverage.

Example: When an A4 sized sheet is filled in with black toner, the black toner coverage is 100%.

-What is "Toner Refresh"?

1 reason that issues may occur as a result of coverage fluctuations is toner left in the developer for extended periods or high numbers of prints being made without use of much toner. The longer the toner is left in the developer, the more the toner degrades, resulting in distortions to the image.

Be sure to perform "Toner Refresh" before commencing the job.

Take out any old toner and fill the developer with new toner to help stabilize image quality. For details, refer to [Execute Adjust Operation].

When Printing Large Volumes or Important Jobs

Use the "Auto Image Adjustment" function if Intelligent Quality Care Unit IQ-501 is mounted to the system.

What is the "Auto Image Adjustment" function?

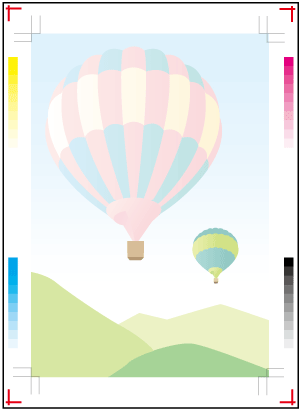

Auto Image Adjustment is a function that automatically prints adjustment crop marks and gradation patches in the trim margin of the printed item, which are then scanned and corrected by the sensor on Intelligent Quality Care Unit IQ-501.

Corrects the image position and any gradation misalignment in real time, improving image stability during printing.

For details about the operation method, refer to To Perform Auto Image Adjustment.

Setting Procedure

Make the following adjustments when printing in large volumes, or when printing jobs in which color is important. Doing this helps stabilize the image quality of the printed item.

For details, refer to [Toner Refresh Mode] in [Execute Adjust Operation].

To achieve a stable both-side accuracy or immediately before outputting a job in which both-side accuracy is important, perform the both-side adjustment.

For details, refer to Adjustment Workflow for Each Job.

Just before printing a job for which shading is important, adjust the image quality.

For details, refer to Daily Adjustment Flow (High Precision).

When Reprinting Previously Printed Jobs

To print previously printed jobs with the same finish as the original print, you can improve reproducibility by creating and using "image position" and "image quality" adjustment values set as reference values previously.

The 3 operations that must be performed are listed below.

Create image position and image quality adjustment values

Register these adjustment values as reference values and use them accordingly

Perform calibration to improve image quality reproducibility

Setting Procedure

Register image position adjustment values: Adjustment Flow for When Using New Types of Paper

Register image quality adjustment values automatically: [Each Paper Type Color Adj.] (For Intelligent Quality Care Unit IQ-501)

Register image quality adjustment values manually: Measure the density adjustment values using the colorimeter and register the values. For details, refer to the ColorManager User's Guide.

Set the image position adjustment value: [Recall] or [No. Recall]

Set the image quality adjustment value: [Color Density]

Performing automatically: [Basic Setting] - [Periodical Adj. Execution]

Performing manually: [Color Density Manual Control]

in the upper-right of a page, it turns into

in the upper-right of a page, it turns into  and is registered as a bookmark.

and is registered as a bookmark.