Adjustment: Image Quality

About Image Quality Adjustment

Issues may arise during printing which mean that the intended colors cannot be reproduced on the system.

Issues with the reproduction accuracy of the color can occur because of changes in the system's ambient temperature or humidity, changes in the system's condition, or changes in the type of paper being used.

Perform "Image Quality Adjustment" regularly in order to maintain stable image quality.

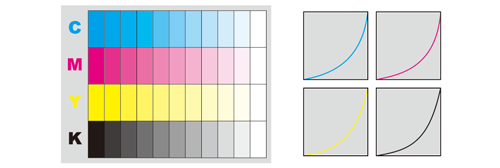

"Image Quality Adjustment" is a process for making adjustments so that you can reproduce the intended color on the system. Adjust the input and output curves for each CMYK color in an image to get closer to the desired color.

What Is the Image Stabilizing Control Function?

The system includes an automatic function called the "Image Stabilizing Control Function" that helps you to make image quality adjustments.

It reduces the user's workload for image quality adjustment and stabilizes the image at a constant quality.

The Image Stabilizing Control Function allows the system to make a variety of automatic corrections when conditions that require image stabilizing type corrections are detected. The items that can be corrected are described below.

Item | Description |

|---|---|

Long correction control | Corrects for changes in image output density that occur as a result of the system not being used for long periods, changes in the ambient humidity, or when printing large volumes. |

Image stabilization control | Corrects for changes in output density and line width that occur when making multiple consecutive prints. |

Middle correction control | When changes occur that cannot be corrected using just image stabilization control, the correction values of each correction function are reconstructed. |

Color registration correction control | Corrects for main scan, sub scan, horizontal magnification, and skew deviations. |

Because the corrections are not made with use of charts, factors such as the paper type and characteristics, or whether it was transferred or fused, are not taken into consideration.

In order to perform adjustments and corrections to the image quality at higher accuracies, the user should make the "image quality adjustments" themselves.

Performing Image Quality Adjustments

In order to maintain reproduction accuracy of color reproduction, it is recommended to perform the adjustment workflow detailed below using the system.

The adjustment flow differs depending on the following four timings. For details, refer to the reference page.

When using a new type of paper

When outputting 1,000 to 2,000 copies

When changing the screen

Perform When Finishing Adjustments Are Required After Executing a Job

This chapter describes "Recommended Settings" for different situations.

Setting items may differ depending on the mounted options. For details, refer to the following reference pages.

Describes the sequence of adjustments to be made daily to once every 2 or 3 months. Use this information for normal operations. | |

Describes the adjustments if the image quality is poor. | |

Describes adjustments to be made when you want to change from the standard settings and make color reproduction more stable. | |

Describes adjustments to be made when you want to reduce the amount of waste paper (paper to be disposed) generated during adjustments by changing from the standard settings. | |

Describes adjustments that can be made without reducing productivity by changing from the standard settings. |

in the upper-right of a page, it turns into

in the upper-right of a page, it turns into  and is registered as a bookmark.

and is registered as a bookmark.