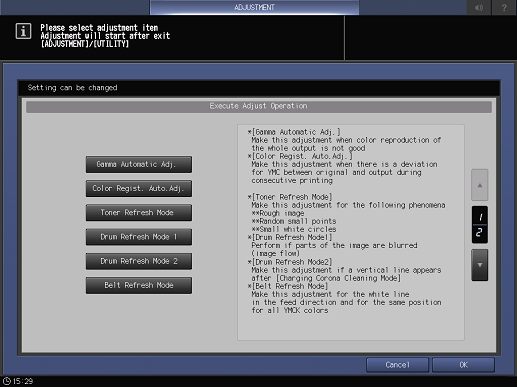

[Execute Adjust Operation]

Overview

This system automatically adjusts the print engine when the power is turned on or before printing starts; however, image quality failures may occur during continuous printing.

Selecting some adjustment items and making continuous readjustments to solve this failures is referred to as "adjustment operation".

After selecting an adjustment item, press [OK] and [Exit [ADJUSTMENT]] to return to the [MACHINE] screen; adjustment starts automatically.

Setting Items

Screen access

Touch panel - [MACHINE] - [Adjustment] - [Execute Adjust Operation]

Setting item | Description |

|---|---|

[Gamma Automatic Adj.] | Detects the status of toner and the transfer belt using the sensor, and automatically adjusts so that the appropriate color reproduction is obtained. |

[Color Regist. Auto.Adj.] | Detects the CMYK toner overlapping condition using the sensor, and automatically adjusts so that no misalignment occurs. |

[Toner Refresh Mode] | Refreshes the toner status. This function is available when image degradation, random small dots, or small circular white blank spots occur. |

[Drum Refresh Mode 1] | Refreshes the photoreceptor status. This item is available when an image blur or image flow appears on an image. |

[Drum Refresh Mode 2] | Refreshes the photoreceptor status. Execute this function when vertical streaks appear after [Charging Cleaning Mode]. |

[Belt Refresh Mode] | Polishes the surface of the intermediate transfer belt. This function is available when white lines are detected at the same position in full color mode. |

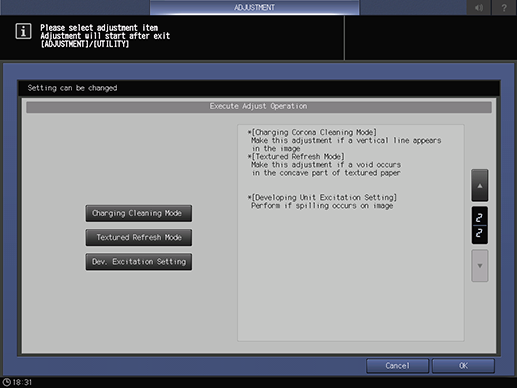

[Charging Cleaning Mode] | Refreshes the status of the charging section. This item is available when vertical streaks appear on an image. |

[Textured Refresh Mode] | Available when white streaks appears in concave portions of textured paper. |

[Dev. Excitation Setting] | Refreshes the status of the developing machine. This item is available when a spill appears on an image. |

in the upper-right of a page, it turns into

in the upper-right of a page, it turns into  and is registered as a bookmark.

and is registered as a bookmark.