[Common Setting]

Overview

Set the common items in [User Setting] and [Administrator Setting].

You can change the message display time and other settings on the Touch panel. You can carry out your work more efficiently by changing the setting according to the purpose of use.

Setting Items

Setting item | Description | |

|---|---|---|

[One Shot Message Indication Time] | Select the display time of the message that is displayed momentarily in the message display area on the Touch panel. | |

[Offset by Job Unit] | Configure the setting to perform output offset every specified number of jobs. Using this function facilitates offset for each job. Range: 1 to 9999 | |

[Continuation Print] | Set whether or not to output successive copy jobs or print jobs continuously without stopping the machine at each job break. | |

[Back Side Magnification Adjustment] | Set whether or not to adjust the lengthwise magnification (zoom ratio in the paper feed direction) of the back side during 2-sided printing. | |

[Fusing Stability (Mixed Media)] | [Best Quality] | Places top priority on image quality for fusing. The processing speed may be reduced. |

[Better Quality] | Places priority on image quality for fusing. | |

[Speed] | Places priority on speed for fusing. The image quality may become unstable. | |

[Highest Speed] | Places top priority on speed for fusing. The image quality may become unstable. | |

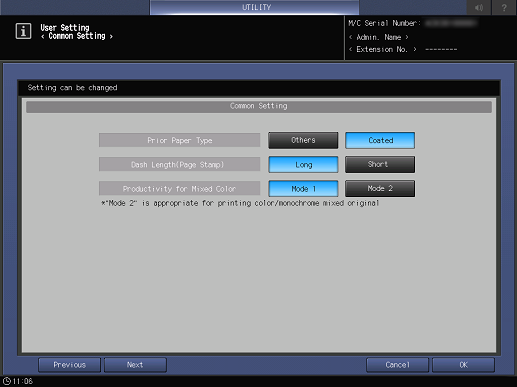

[Prior Paper Type] | [Others] | Places priority on paper other than the coated paper to maintain the temperature of the fusing unit when this system is on standby for printing and no paper tray is selected. |

[Coated] | Places priority on the coated paper to maintain the temperature of the fusing unit. | |

[Dash Length(Page Stamp)] | Set the length of the bar symbol, "dash", that is used in page stamps. * For print jobs, the settings may not work depending on the type of the Image Controller mounted on the machine. | |

[Productivity for Mixed Color] | [Mode 1] | Set the mode suitable for printing the colored original. |

[Mode 2] | Set the mode suitable for printing the original mixed in color and monochrome. | |

[Center Crop Mark Trim Margin] | Set the interval to be added to the interval between the center crop mark and the original image area. Range: 0.0 mm to 20.0 mm | |

[Hold Job Status after Output (Default)] | Set the default for automatically deleting hold jobs after printing. The setting can be changed in [With Job Delete] when printing. | |

[Offset Output Mode] | [Change Out Pos.] | Switches the paper output position on the output tray. |

[Stop Print] | Stops printing. To continue printing, press Start. | |

[Change Out Pos. + Partition Paper] | Switches the paper output position on the output tray, and inserts partition paper. When setting this item, you need to select the paper tray loaded with partition paper. | |

[Partition Paper] | Inserts partition paper. When setting this item, you need to select the paper tray loaded with partition paper. | |

[Hold Job Direct Output (Default)] | Set the default of the [Direct Output] check box at the bottom of the [Hold Job] screen. The setting can be changed in [Hold Job]. * After changing the setting, turn off Sub power switch once before using this system. | |

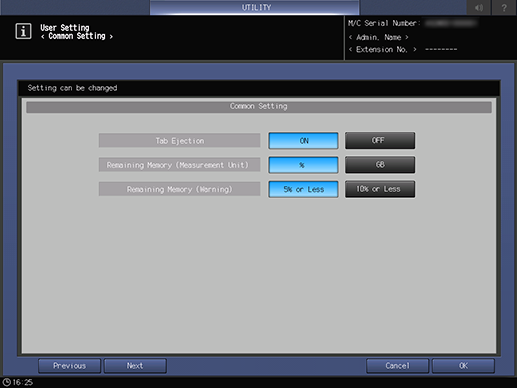

[Tab Ejection] | Set whether or not to automatically output unnecessary tab paper loaded in the paper tray that is used for a job. | |

[Remaining Memory (Measurement Unit)] | Set the display unit of the remaining memory. | |

[Remaining Memory (Warning)] | Set a reference value to display a warning when the remaining amount of available memory in the HDD is low. | |

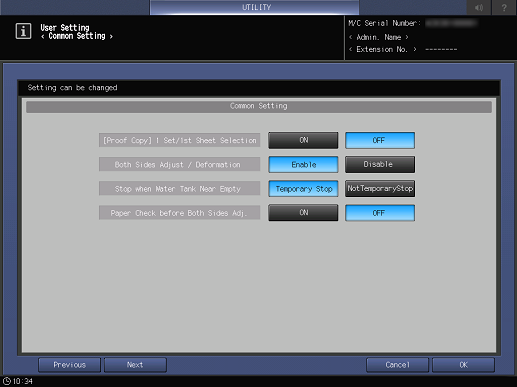

[[Proof Copy] 1 Set/1st Sheet Selection] | Make settings to display the selection screen of Proof Copy that checks the finish by copying a small amount in advance. | |

[Both Sides Adjust / Deformation] | Set whether or not to use the [Deformation] function of [Both Sides]. | |

[Stop when Water Tank Near Empty] | Set whether or not to temporarily stop printing when the water in the humidification tank runs low. This is displayed when Relay Unit RU-518m with Humidifier HM-103 is mounted. | |

[Paper Check before Both Sides Adj.] | Set the default for [Both Sides] - [AutoMeasure] - [Paper Check] of the MACHINE function keys. | |

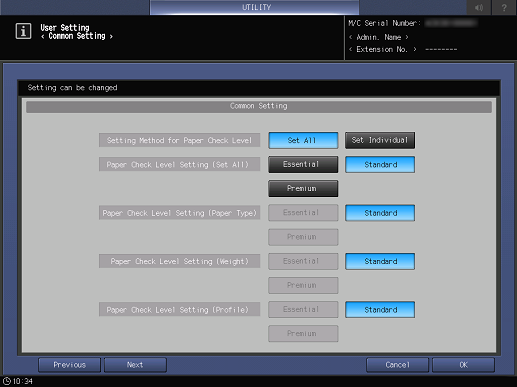

[Setting Method for Paper Check Level] | Select the method to set the inspection standard for paper check. * If [Set All] is selected, the following items cannot be set individually. They are automatically set to the inspection standard of [Paper Check Level Setting (Set All)].

| |

[Paper Check Level Setting (Set All)] | Collectively set the inspection standards of the paper type, weight, and paper profile for paper check. | |

[Paper Check Level Setting (Paper Type)]*1 | Set the inspection standard of the paper type for paper check. | |

[Paper Check Level Setting (Weight)]*1 | Set the inspection standard of the weight for paper check. | |

[Paper Check Level Setting (Profile)]*1 | Set the inspection standard of the paper profile for paper check. | |

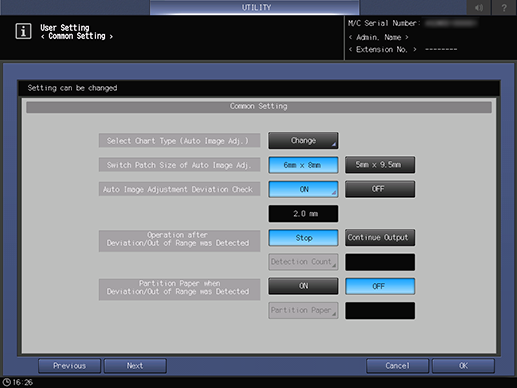

[Select Chart Type (Auto Image Adj.)]*2 | Select the chart type when automatically adjusting the image quality for each paper weight. | |

[Switch Patch Size of Auto Image Adj.]*2 | Set the patch size that is printed on a chart for automatic image adjustment. | |

[Auto Image Adjustment Deviation Check]*2*3 | Set whether or not to automatically check a deviation. Range: 0.5 mm to 10.0 mm | |

[Operation after Deviation/Out of Range was Detected]*2*3 | [Stop] | Stops printing when a deviation or non-standard image is detected. |

[Continue Output] | Continues printing even if a deviation or non-standard image is detected. | |

[Detection Count] | Sets the number of deviations or non-standard images detected before printing is stopped while [Continue Output] is selected. Range: 0 to 10 | |

[Partition Paper when Deviation/Out of Range was Detected]*2*3 | Configure the setting to insert partition paper when output paper does not satisfy the standard. [Partition Paper]: Sets the paper tray to load partition paper into. | |

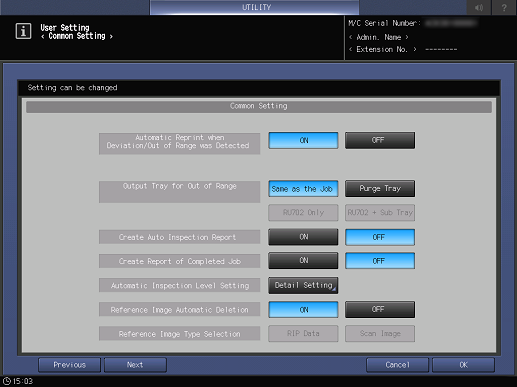

[Automatic Reprint when Deviation/Out of Range was Detected]*2*3 | Configure the setting to re-print a job when output paper does not satisfy the standard. When re-printing, paper in this system is output once, so no page order error occurs on output paper. * This item is not displayed when Image Controller manufactured by Fiery is mounted on this system. | |

[Output Tray for Out of Range]*3*4 | [Same as the Job] | Ejects paper to the same output tray as a job when output paper does not satisfy the standard. |

[Purge Tray] | Ejects paper to Purge tray when output paper does not satisfy the standard. | |

[RU702 Only] | Ejects paper only to the Purge tray of Relay Unit RU-702 when output paper does not satisfy the standard. This setting is available when [Purge Tray] is selected. | |

[RU702 + Sub Tray] | Ejects paper to the Purge tray of Relay Unit RU-702 and Secondary (sub) tray of another unit when output paper does not satisfy the standard. This setting is available when [Purge Tray] is selected. * If the available Secondary (sub) tray is not provided in Relay Unit RU-702 or later inactive. | |

[Create Auto Inspection Report]*3 | Configure the setting to create an automatic inspection result report. If output paper that does not satisfy the standard is not ejected automatically, the user processes non-standard output paper based on the report. | |

[Create Report of Completed Job]*3 | Configure the setting to create an automatic inspection report within the standard. You can create an inspection result report for the output paper with the standard satisfied. | |

[Automatic Inspection Level Setting]*3 | Press [Detail Setting] to set the inspection standard for automatic inspection. You can change the inspection level according to the type of stain or output-related issue. | |

[Reference Image Automatic Deletion]*3 | Configure the setting to automatically delete the reference image created by automatic inspection. | |

[Reference Image Type Selection]*5 | Set the reference image type for automatic inspection. If [RIP Data] is selected, the RGB image created by the Image Controller is saved as a reference image. The black background contained in the scanned image is deleted, so the high-precision automatic inspection becomes possible. If [Scan Image] is selected, the image scanned by the Intelligent Quality Care Unit IQ-501 is saved as a reference image. | |

[Setting for Inspect. of Excluded Areas]*3 | Set the default Inspection Excluding Area for automatic inspection. | |

[Counted Error by Each Level]*3 | Totalize the detected stains and omissions by level and display the result in the automatic inspection result report. | |

[Text for OCR]*3 | Set the characters that can be read with OCR. Select the target characters when reading the scanned image as characters. | |

[Output Tray for Reference Image Job]*3 | Set the destination where to output a reference image job. When [Sub Tray] is selected, the following conditions must be satisfied.

| |

*1 The following setting is required to use this function.

Set [Setting Method for Paper Check Level] to [Set Individual]

*2 All the following options are required to use this function. Also, enable the [Auto Image Adjustment] function using the PS Plug-in Driver or AccurioPro Print Manager.

Intelligent Quality Care Unit IQ-501

Video Interface Kit VI-514

*3 All the following options are required to use this function. Also, enable the [Auto Inspection] function using the PS Plug-in Driver or AccurioPro Print Manager.

Intelligent Quality Care Unit IQ-501

Auto Inspection Unit UK-301

Relay Unit RU-702

Video Interface Kit VI-514

Video Interface Kit VI-515

*4 The paper cannot be output to the following tray.

FoldingUnit FD-503

SaddleStitcher SD-506

Secondary (sub) tray of Trimmer Unit TU-510

The paper cannot be output to the Secondary (sub) tray of Saddle Stitcher SD-513 in Multi Tri-Fold, Fold & Staple, or Half-Fold mode.

*5 All the following options are required to use this function.

Intelligent Quality Care Unit IQ-501

Auto Inspection Unit UK-301

Relay Unit RU-702

Video Interface Kit VI-514

Video Interface Kit VI-515

Inspection Enhancement Kit UK-311

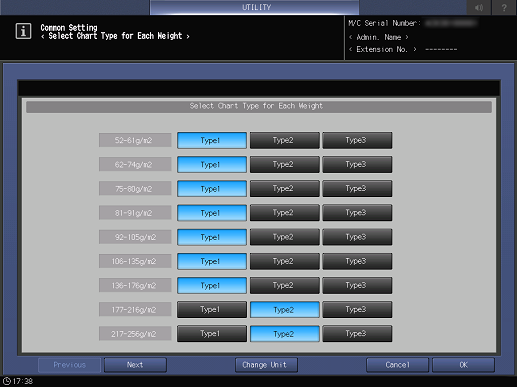

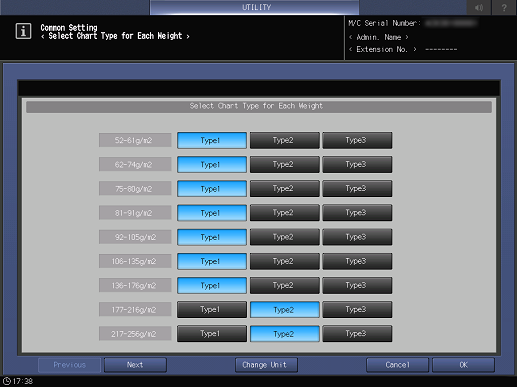

Setting Procedure ([Select Chart Type (Auto Image Adj.)])

Each time [Change Unit] is pressed, the weight display unit is switched.

The crop mark printing position and length vary for each type.

Default:

135 g/m2 or less: [Type1]

136 g/m2 or more: [Type2]

The following chart types are selectable in step 2.

Other than banner paper (487.7 mm or less in paper feed direction) | [Type1] | [Type2] | [Type3] | |

|---|---|---|---|---|

Distance from paper edge to crop mark | Paper feed direction | 2.0 mm | 9.0 mm | 4.0 mm |

Crosswise direction | 2.0 mm | 2.0 mm | 2.0 mm | |

Crop mark length | Width | 5.0 mm | 5.0 mm | 5.0 mm |

Height | 6.0 mm | 6.0 mm | 6.0 mm | |

Other than banner paper (487.8 mm or more in paper feed direction) | [Type1] | [Type2] | [Type3] | |

|---|---|---|---|---|

Distance from paper edge to crop mark | Paper feed direction | 2.5 mm | 9.0 mm | 4.0 mm |

Crosswise direction | 2.5 mm | 2.5 mm | 2.5 mm | |

Crop mark length | Width | 4.5 mm | 4.5 mm | 4.5 mm |

Height | 5.5 mm | 5.5 mm | 5.5 mm | |

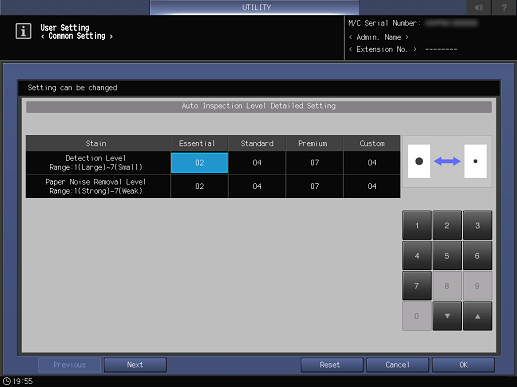

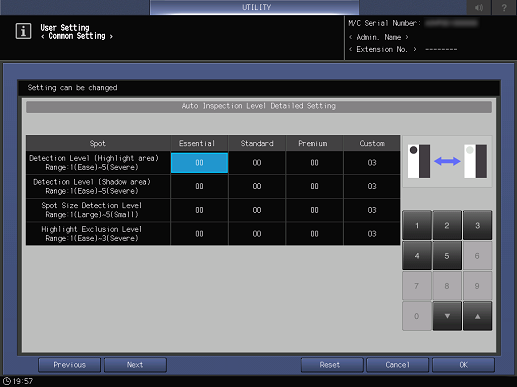

Setting Procedure ([Automatic Inspection Level Setting])

[Essential] to [Premium] are inspection levels to be set in AccurioPro Print Manager or PS Plug-in Driver. For details, refer to [Quality].

[Custom] is an inspection area when [Specified Level Area] for inspection area setting is specified. For details, refer to [Specified Level Area].

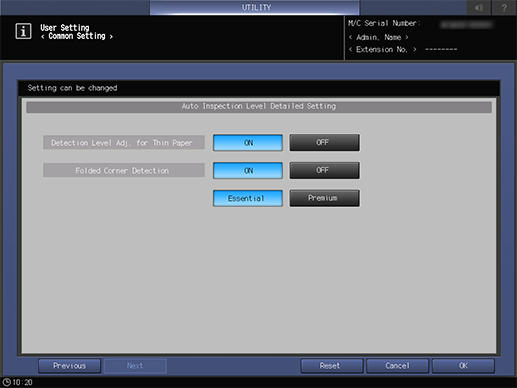

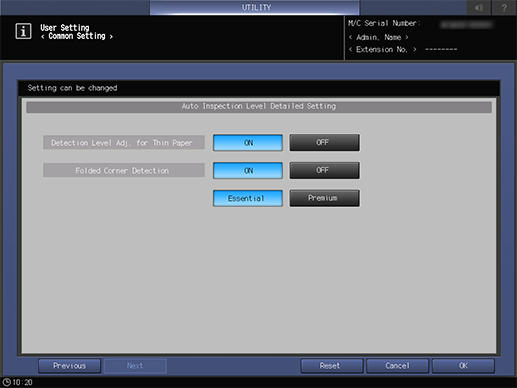

The [Streak] (streak stains) or [Spot] (circular stains) inspection and [Detection Level Adj. for Thin Paper] are optional functions. These functions are not displayed by default. To use this setting, please contact your service representative.

For [Detection Level Adj. for Thin Paper], press [ON] or [OFF].

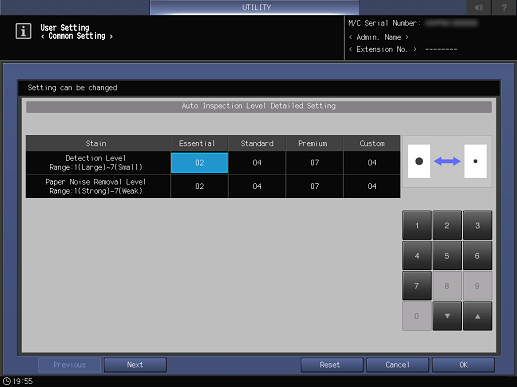

The adjustable inspection level types are as follows.

Setting item | Description | ||

|---|---|---|---|

Stain | [Detection Level] | Adjusts the size standard of a stain to be detected. |  |

[Paper Noise Removal Level] | Adjusts the density standard of a stain to be detected. |  | |

Streak Stain | [Detection Level] | Adjusts the density standard of a streak stain to be detected. |  |

[Highlight Exclusion Level] | Adjusts the level to exclude an image, which is seen through from the back, from the detection target when detecting a streak stain. |  | |

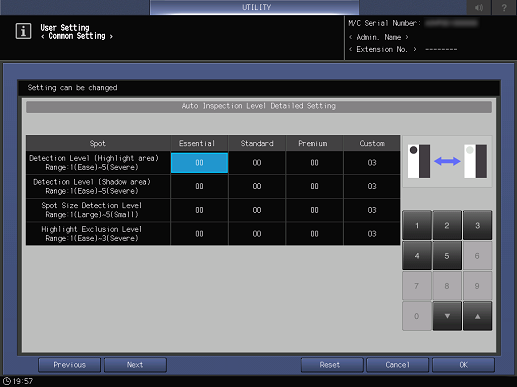

Spot | [Detection Level (Highlight area)] | Adjusts the density standard of a stain to be detected when inspecting a light part on an image. |  |

[Detection Level (Shadow area)] | Adjusts the density standard of a stain to be detected when inspecting a dark part on an image. |  | |

[Spot Size Detection Level] | Adjusts the size standard of a spot to be detected. |  | |

[Highlight Exclusion Level] | Adjusts the level to exclude an image, which is seen through from the back, from the detection target when detecting a spot. |  | |

Others | [Detection Level Adj. for Thin Paper] | Set whether to adjust the detection level when using thin paper. | |

[Folded Corner Detection] | Set whether to detect folded corners and chipped edges of output paper. If you select [ON], you can set the detection criteria. [Essential]: Detects folded corners and chipped edges of output paper of 5 mm or more. [Premium]: Detects folded corners and chipped edges of output paper of 0.5 mm to 1 mm or more. | ||

in the upper-right of a page, it turns into

in the upper-right of a page, it turns into  and is registered as a bookmark.

and is registered as a bookmark.